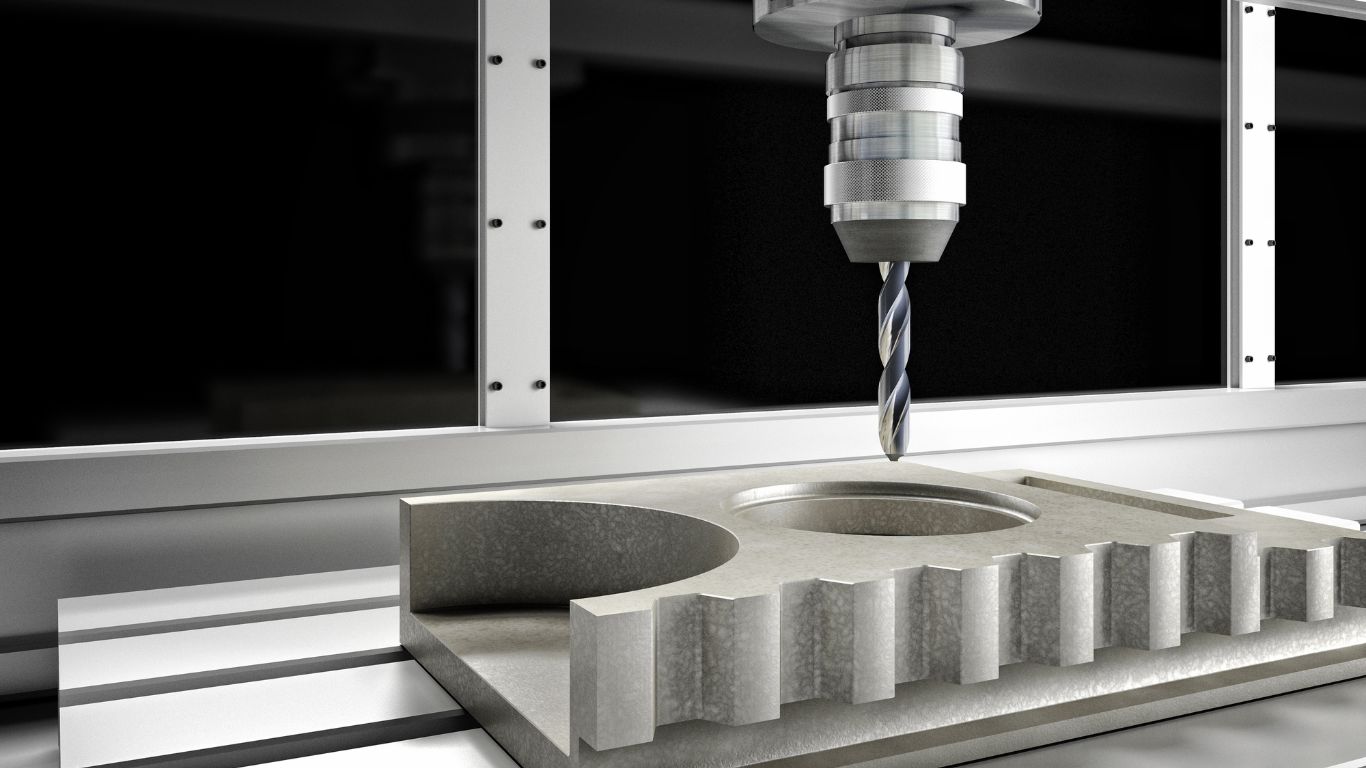

Solid carbide drills are cutting tools designed for creating precise holes in various materials. These drills are made entirely from carbide, a compound of carbon and metal, typically tungsten. They offer excellent performance, durability, and accuracy for drilling operations in manufacturing and metalworking.

We often use solid carbide drills in applications that require high precision and efficiency. They excel at drilling holes in tough materials like steel, stainless steel, and cast iron. Their hardness and wear resistance allow them to maintain sharpness and dimensional stability even under demanding conditions.

Solid carbide drills come in different sizes and styles to suit various drilling needs. They can achieve tight tolerances and produce high-quality holes. While they may cost more upfront than other drill types, their long lifespan and ability to be reconditioned make them a cost-effective choice for many machining operations.

Overview of Solid Carbide Drills

Solid carbide drills are cutting tools made from a single piece of tungsten carbide. We use them for making precise holes in various materials during machining operations.

These drills offer excellent performance and accuracy. They can achieve tight tolerances, often up to IT8 precision levels.

Solid carbide drills come in different types for specific applications:

- WTX-UNI: General purpose

- WTX-VA: Stainless steel

- WTX-H: Hardened materials

- WTX-AI: Aluminum

- WTX-Ti: Titanium

The main benefits of solid carbide drills include:

- High hardness and durability

- Good hole quality

- Excellent process security

- Fast penetration rates

We commonly use these drills on materials like steel, stainless steel, cast iron, and non-ferrous metals. They work well for both short and deep holes.

Solid carbide drills can be reconditioned to extend their life and improve cost efficiency. This makes them a smart choice for many manufacturing operations.

With their versatility and high performance, solid carbide drills have become essential tools in modern machining processes.

Materials and Applications

Solid carbide drills are versatile tools used across many industries. They excel in drilling holes in a wide range of materials, from common metals to specialized alloys.

Drilling in Metals

Solid carbide drills work great for drilling holes in steel, stainless steel, and cast iron. We use them a lot in the automotive and aerospace industries. These drills can handle high speeds and heavy loads without breaking.

For steel, we pick drills with special coatings to reduce friction and heat. This helps the drill last longer. When drilling stainless steel, we use drills with stronger cutting edges to deal with the tough material.

Cast iron can be tricky to drill, but solid carbide drills do a good job. We choose drills with thick coatings to protect against the abrasive nature of cast iron.

Non-Ferrous Materials

Solid carbide drills also work well on non-ferrous metals like aluminum, brass, and copper. These materials are softer than steel, so we use different drill designs.

For aluminum, we pick drills with polished flutes. This stops chips from sticking to the drill. Brass and copper need drills with sharp cutting edges to make clean holes.

Here’s a quick list of non-ferrous materials we often drill:

- Aluminum and its alloys

- Brass

- Copper

- Bronze

- Titanium

Specialized Materials

Solid carbide drills can handle tough jobs on hardened steels and alloys. We use these drills in the tool and die industry and for making high-strength parts.

For very hard materials, we pick drills with special coatings like diamond or cubic boron nitride. These coatings help the drill cut through super hard surfaces.

Some examples of specialized materials we drill:

- Hardened tool steels

- Nickel-based alloys

- Titanium alloys

- Composite materials

Solid carbide drills with the right design can even drill through tough composites used in aerospace and sports equipment.

Manufacturing and Design

Solid carbide drills are precision tools made through careful engineering. Their production involves specialized materials and processes to create durable, high-performance cutting tools.

Material Composition

We start with a blend of tungsten carbide powder and cobalt. Tungsten carbide gives the drill its hardness, while cobalt acts as a binder. The mix typically contains 6-12% cobalt. More cobalt makes the drill tougher but less wear-resistant. Less cobalt increases hardness but can make the drill brittle.

The powder blend is pressed into shape and then sintered. Sintering heats the material to near its melting point. This fuses the particles together, creating a solid, dense structure. The result is a drill blank ready for further processing.

Coatings and Surfaces

Coatings boost drill performance and life. Common options include:

- TiN (titanium nitride): Improves wear resistance

- TiAlN (titanium aluminum nitride): Offers heat resistance

- Diamond: Provides extreme hardness for non-ferrous materials

Coatings are applied through processes like physical vapor deposition (PVD) or chemical vapor deposition (CVD). These create thin, even layers on the drill surface.

Some drills use special surface treatments instead of coatings. These can include shot peening or micro-blasting to enhance surface properties.

Geometry and Grinding

The final shape of a solid carbide drill is crucial for its performance. Key features include:

- Point angle: Typically 118° or 135°

- Flute design: Affects chip evacuation

- Margin width: Impacts hole finish and stability

We use precision grinding machines to shape these features. Computer-controlled grinders can create complex geometries with tight tolerances. This process defines the cutting edges, flutes, and other critical surfaces.

The tip may be ground to special shapes like split-point or four-facet designs. These improve centering and cutting action. After grinding, drills often undergo a final polishing step to refine the surface finish.

Performance Factors

Solid carbide drills offer several key benefits that impact machining performance. These drills excel in speed, durability, and precision compared to other options. Let’s examine the main factors that contribute to their effectiveness.

Machining Time Efficiency

Solid carbide drills allow for faster machining speeds. We can run these tools at higher spindle speeds and feed rates than HSS drills. This means we can drill holes more quickly and boost productivity.

Carbide’s heat resistance lets us maintain high speeds without the drill wearing down rapidly. In many cases, we can drill 2-4 times faster with carbide versus HSS.

The rigid structure of solid carbide also reduces vibration at high speeds. This stability helps maintain accuracy even when pushing the drill to its limits.

Tool Durability and Wear

Solid carbide drills last much longer than HSS alternatives. We often see 5-10 times more holes drilled before needing to replace a carbide drill.

The hardness of carbide resists abrasive wear, especially when drilling tough materials. This means less frequent tool changes and more uptime.

Coatings like TiAlN further improve durability. These thin films protect the carbide and can double tool life in some applications.

Heat resistance is another key factor. Carbide keeps its hardness at high temps, so the cutting edges stay sharp longer during extended use.

Cutting Precision

We can achieve tighter tolerances with solid carbide drills. Their rigid structure reduces deflection, resulting in straighter and more accurate holes.

Carbide’s strength allows for sharper cutting edges. This produces cleaner hole walls with less burring or chipping.

The stability of carbide at high speeds also improves hole quality. We see less wandering or drifting of the drill, even in deep hole applications.

For precision work, solid carbide can often hit IT8 tolerances. This level of accuracy is hard to match with other drill types.

Tool Selection and Usage

Picking the right solid carbide drill and using it properly makes a big difference. We’ll look at how to choose drills for different jobs and keep them in good shape.

Determining the Right Drill

We need to think about the material we’re drilling when selecting a drill. Soft metals need different drills than hard ones. For example, drills for aluminum are not the same as those for steel.

Multi-purpose drills like the Kenna Universal™ work on many materials. But special drills may be better for tough jobs. The grade of carbide matters too. Tougher grades last longer in hard materials.

Drill size and length are also key. We pick the size based on the hole we need. Longer drills are good for deep holes but can wobble more. Shorter ones are more stable.

Drill Security and Maintenance

Taking care of drills helps them last longer. We always use the right speed and feed rates. Going too fast can break drills. Too slow makes them wear out faster.

Cooling is a must. We use cutting fluid or air to keep drills cool and clear chips. This stops them from overheating or getting stuck.

Regular checks for wear are important. Look for chipped edges or dull spots. Replace drills before they break to avoid damaging parts.

Proper storage keeps drills safe. We put them in holders or boxes to protect the cutting edges. This way, they stay sharp and ready for the next job.

Advancements in Carbide Drill Technology

Solid carbide drills have seen major improvements in recent years. We’ve witnessed big leaps in design and performance.

New carbide grades are tougher and more heat-resistant. This lets drills work faster and last longer. Coatings have also gotten better. They cut friction and help chips flow away smoothly.

Cutting edge shapes have been refined. Many drills now have special grinds that make cleaner holes. Some key upgrades include:

- Improved flute designs for better chip evacuation

- Stronger web cores to prevent breaking

- Optimized point angles for different materials

Tool makers like Kennametal are pushing innovation. Their HPX line brings together several new features. These drills can often double or triple productivity.

Software advances help too. We can now design and test drills virtually. This speeds up development of new models.

3D printing is changing things as well. It lets us make complex internal cooling channels. These keep drills cooler during tough jobs.

The result? Today’s solid carbide drills work faster, last longer, and make better holes. They can handle tougher materials with ease. For many shops, upgrading to new carbide drills is a smart move.

Frequently Asked Questions

Solid carbide drills are versatile tools used in many drilling applications. They offer unique benefits and have specific uses across industries.

What are solid carbide drills primarily utilized for?

Solid carbide drills excel at creating precise holes in tough materials. We use them for drilling metals, composites, and other hard substances. These drills can make small, deep holes with tight tolerances.

How do solid carbide drills differ from HSS drills?

Solid carbide drills are harder and more heat-resistant than HSS (High-Speed Steel) drills. They can drill faster and last longer when used correctly. Carbide drills also maintain their sharp edge better during use.

What are the advantages of using a solid carbide drill bit set?

A solid carbide drill bit set offers improved drilling speed and accuracy. These bits can handle higher temperatures without losing their edge. They also produce cleaner holes and have a longer lifespan than other drill bit types.

In what applications is a solid carbide drill used on hardened steel?

We use solid carbide drills on hardened steel when making precise, small-diameter holes. They work well for drilling deep holes in tool steels and other hard metals. Carbide drills can handle the high heat generated when cutting tough materials.

What should be considered when selecting speeds and feeds for Kennametal carbide drills?

When using Kennametal carbide drills, we must consider the material being drilled and the drill’s diameter. Harder materials usually require slower speeds. Larger drill diameters typically need lower RPMs. Proper coolant use is also important for best results.

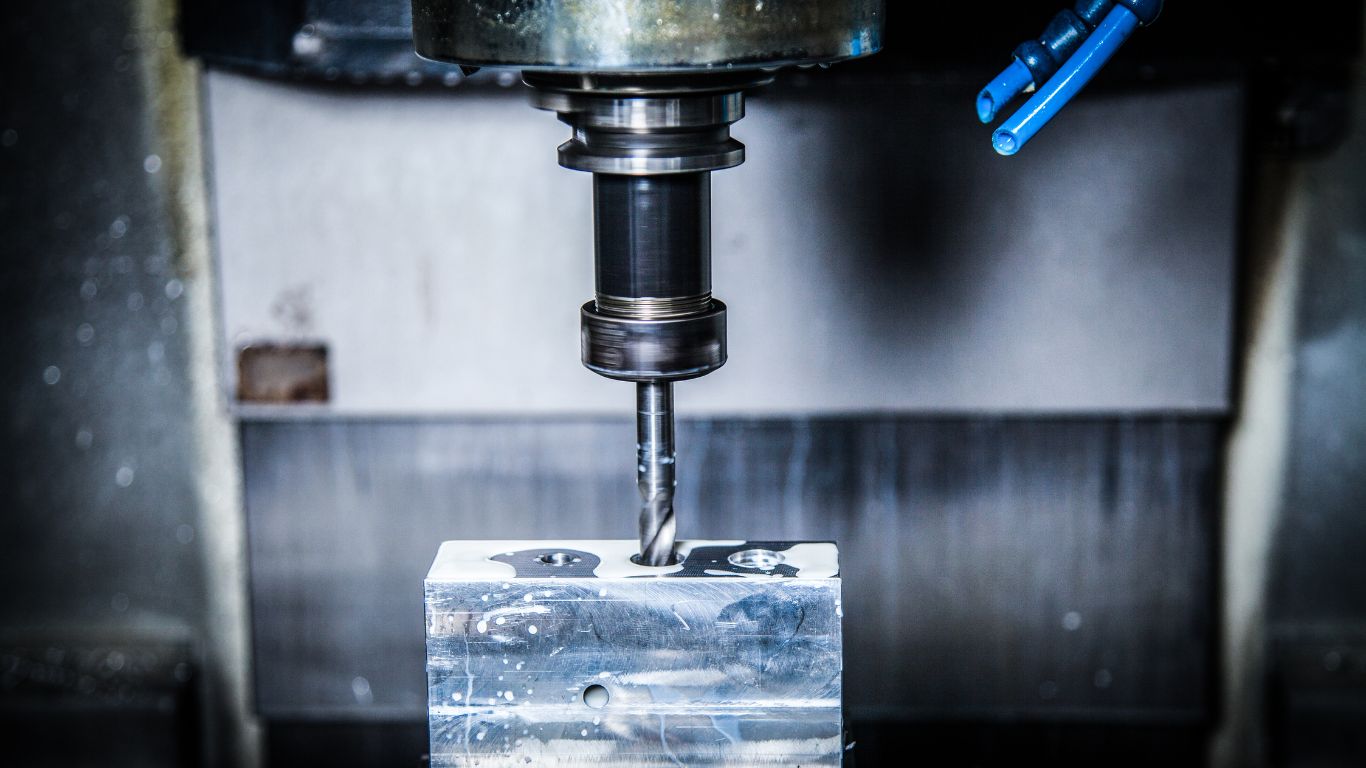

What types of machinery are optimally paired with solid carbide drills?

Solid carbide drills work best with rigid, high-precision machines. CNC machining centers, drill presses, and milling machines are good choices. These tools need machines that can provide stable, consistent drilling conditions for optimal performance.