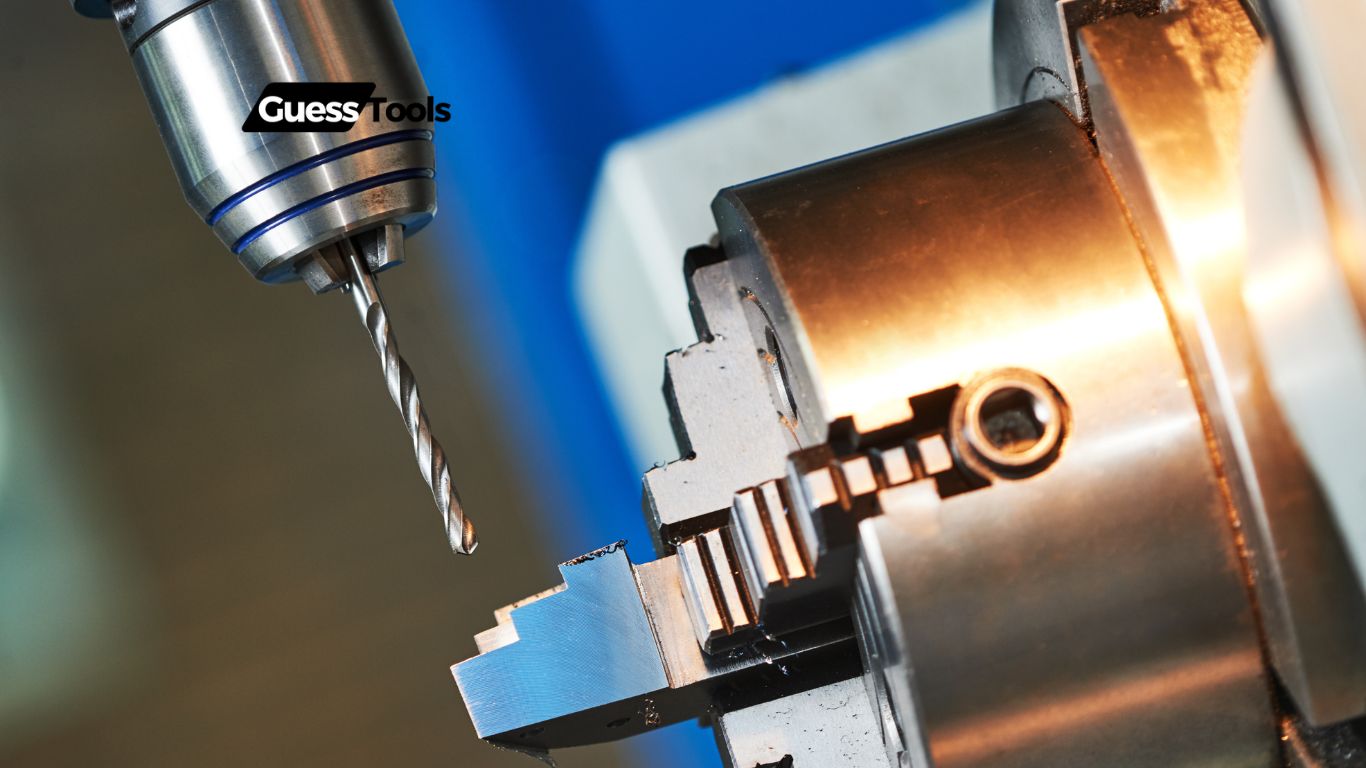

What is deep hole drilling? It’s a special way to make long, narrow holes in materials like metal. Deep hole drilling is defined by a depth-to-diameter ratio greater than 10:1, allowing for precise, straight holes with excellent surface finishes. This method differs from regular drilling because it needs special tools and techniques to keep the hole straight and accurate.

We see deep hole drilling used in many industries today. From gun barrels (where it began) to aerospace parts, automotive components, and medical equipment. What makes this process unique is how cooling lubricant must be pumped to the cutting edges under high pressure. This helps cool the drill and lubricate the contact areas between the workpiece and cutting tool.

When you need highly accurate, repeatable holes with superior finishes, deep hole drilling is the way to go. It offers precision and efficiency that standard drilling methods can’t match for those challenging projects requiring long, narrow holes. Different types of deep hole drilling techniques exist, each suited for specific applications and materials.

Types Of Deep Hole Drilling Techniques

Deep hole drilling comes in several forms, each with its own benefits for specific applications. These techniques have been refined over decades to create precise holes with high depth-to-diameter ratios.

BTA (Boring And Trepanning Association) Drilling

BTA drilling is perfect for larger diameter holes, typically ranging from 0.8 to 24 inches. Unlike other methods, the coolant flows through the gap between the tool and workpiece, then exits with chips through the center of the drill.

What makes BTA special? The cutting head attaches to a hollow boring bar with a single point. This design allows for:

- Vyšší miery úberu materiálu than gun drilling

- Better straightness in deep holes

- Improved surface finish quality

- Capability to drill holes with depth-to-diameter ratios up to 100:1

The BTA process uses external coolant delivery, which helps flush chips efficiently and prevents them from scratching the newly formed hole surface.

Gun Drilling

Gun drilling is named after its original use in making gun barrels. It’s ideal for smaller diameter holes, usually between 0.08 and 1.25 inches.

How does it work? A gun drill has a single cutting edge with internal coolant channels. The coolant flows through the tool and exits near the cutting edge, helping to:

- Clear chips away from the cutting zone

- Cool the drill bit during operation

- Lubricate the cutting process

- Achieve depth-to-diameter ratios of 20:1 or greater

We find gun drilling particularly useful for creating precise, straight holes in long workpieces. The method excels in applications requiring tight tolerances and excellent surface finish.

Comparison Between Techniques

When choosing between these methods, several factors come into play:

| Funkcia | BTA Drilling | Gun Drilling |

|---|---|---|

| Diameter Range | 0.8-24 inches | 0.08-1.25 inches |

| Depth Capability | Up to 100:1 ratio | Up to 20:1 ratio |

| Chip Removal | Through center of drill | External V-groove |

| Coolant Flow | External to internal | Internal to external |

| Production Speed | Faster for large holes | Better for small diameters |

Material hardness also affects your choice. Gun drilling works well with harder materials, while BTA drilling handles softer materials more efficiently.

Cost considerations matter too. BTA systems typically require more expensive equipment but can achieve higher production rates for larger holes.

Aplikácie v priemysle

Deep hole drilling technology has found its way into numerous sectors, transforming manufacturing processes across the industrial landscape. These specialized drilling techniques solve unique challenges that conventional drilling methods simply can’t handle.

Automotive

In the automotive industry, deep hole drilling plays a crucial role in creating engine components that require precision and durability. We commonly see this technique used for:

- Engine blocks and cylinder heads

- Fuel injection systems

- Transmission shafts

- Crankshafts and camshafts

These parts often need holes with depth-to-diameter ratios exceeding 10:1 while maintaining tight tolerances. For example, oil galleries in engine blocks require perfectly straight passages to ensure proper lubrication under high pressures and temperatures.

The process helps car manufacturers produce reliable parts that can withstand the stress of daily operation. With improved surface finishes that enhance chip removal, these components last longer and perform better.

Aerospace

The aerospace sector relies heavily on deep hole drilling for critical components where failure isn’t an option. We find this technique essential for:

- Hydraulic systems in landing gear

- Engine turbine shafts

- Structural components in wings and fuselage

- Fuel delivery systems

These applications demand extreme precision as safety is paramount in aircraft manufacturing. Deep hole drilling allows us to create cooling channels in turbine blades that prevent overheating during flight.

The ability to drill long, straight holes through tough materials like titanium and high-temperature alloys makes this process invaluable. Aerospace engineers appreciate how these techniques maintain tight tolerances even when working with difficult-to-machine materials.

Energy Sector

In the oil and gas industry, deep hole drilling techniques prove essential for both equipment manufacturing and extraction processes. We see widespread applications in:

- Drilling equipment components

- Subsea valves and manifolds

- Heat exchangers

- Hydraulic cylinders for heavy machinery

The process offers exceptional depth-to-diameter ratios in long workpieces without compromising wall thickness or roundness accuracy. This is crucial when creating boreholes for oil and gas extraction that must withstand extreme pressures.

In power generation, turbine shafts require precisely drilled holes to maintain balance during high-speed rotation. The renewable energy sector also benefits from these techniques in manufacturing specialized components for wind turbines and hydroelectric systems.

Medical

Medical device manufacturing requires the highest levels of precision, making deep hole drilling an ideal process. We commonly utilize this technique for:

- Surgical instruments

- Orthopedic implants

- Dental equipment

- Drug delivery devices

The medical field demands components with excellent surface finishes to prevent contamination and ensure patient safety. Deep hole drilling delivers the smooth, burr-free holes needed for these critical applications.

Bone screws and plates require precise holes with specific surface characteristics to promote healing. The ability to create small diameter holes with exceptional depth makes this process perfect for manufacturing specialized instruments used in minimally invasive surgeries.

Case Studies Showing Real-World Applications

Automotive Fuel Injection Systems A major engine manufacturer needed to drill 1.2mm diameter holes to a depth of 15mm in hardened steel injector nozzles. Using specialized gun drilling techniques, we achieved a remarkable 12.5:1 depth-to-diameter ratio while maintaining position accuracy within 0.01mm.

Aerospace Turbine Cooling For a leading aircraft engine producer, we developed a process to create cooling channels in turbine blades. The challenge was drilling multiple 0.8mm holes through a nickel superalloy to depths of 12mm without deviation. The solution involved custom BTA (Boring and Trepanning Association) tooling that reduced production time by 30%.

Medical Bone Screw Manufacturing A medical device company required 0.5mm diameter holes in titanium bone screws. Using micro-deep hole drilling techniques, we created clean, burr-free holes that met FDA requirements for implantable devices. The process eliminated the need for secondary operations, reducing production costs by 22%.

Advantages And Technical Challenges

Deep hole drilling offers significant benefits but comes with unique technical challenges that manufacturers must address. When performed correctly, this specialized process delivers exceptional results that standard drilling simply cannot match.

Precision And Straightness Capabilities

Deep hole drilling achieves remarkable precision that few other machining processes can match. Modern systems can maintain straightness tolerances of 0.001 inches per 12 inches of depth, which is crucial for applications like fuel injector components and hydraulic systems.

We’ve seen manufacturers achieve hole depth-to-diameter ratios exceeding 300:1 while maintaining tight tolerances. This level of precision isn’t just impressive—it’s often mandatory for critical components.

What makes this possible? The specialized tools use guide bushings and supports that keep the drill centered as it progresses deeper into the material. Think of it like a train staying on tracks rather than a car that might drift off course.

Many high-precision applications also utilize BTA (Boring and Trepanning Association) drilling systems that provide additional stability through their unique cutting design.

Chip Evacuation Systems

Ever wonder how chips don’t clog deep, narrow holes? The answer lies in specialized chip evacuation systems.

In gun drilling (a common deep hole technique), high-pressure coolant flows through the drill’s internal channels directly to the cutting edge. This coolant serves two purposes:

- Cools the cutting edge during operation

- Forces chips back through flutes or channels away from the cutting area

BTA drilling systems work differently—they pump coolant around the outside of the drill and remove chips through the tool’s center. This “reverse flow” system is particularly effective for larger diameter holes.

Without proper chip evacuation, you’ll face:

- Tool breakage

- Poor surface finish

- Dimensional inaccuracies

- Increased production costs

We recommend monitoring tvorba čipov carefully during operations, as changes in chip appearance often signal problems before they become serious.

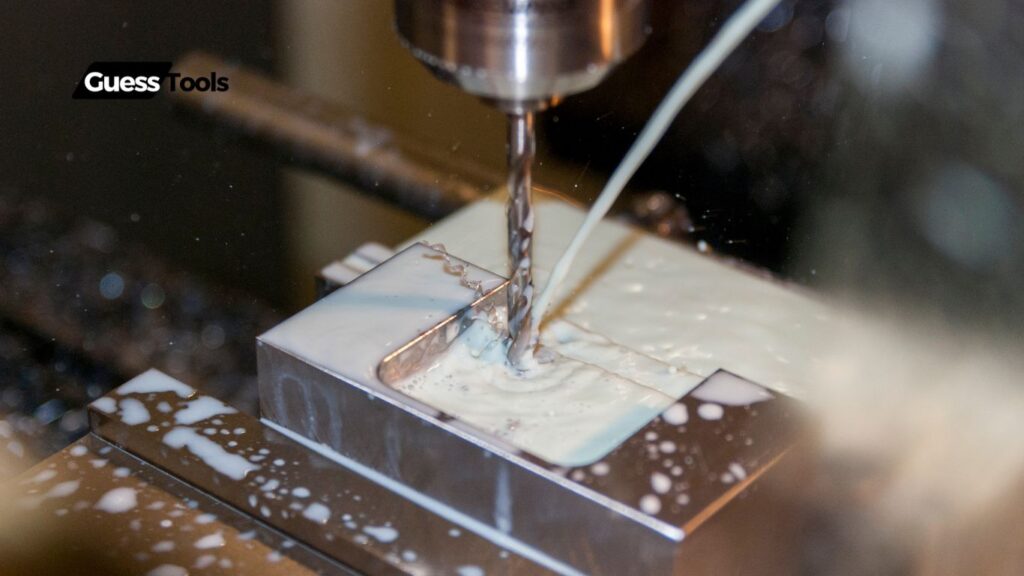

Coolant Management

Coolant management in deep hole drilling isn’t just about cooling—it’s a crucial aspect of the entire process.

Most operations require specialized high-pressure coolant systems that can deliver coolant at 300-1000 PSI depending on the application. This high pressure ensures coolant reaches the cutting edge even in holes that might be several feet deep.

The coolant performs several essential functions:

- Reduces cutting temperature

- Lubricates the cutting interface

- Assists with chip evacuation

- Prevents tool binding

We’ve found that coolant filtration is especially important in deep hole applications. Even small particles can cause scoring on the hole surface or accelerate tool wear.

For difficult materials like titanium or Inconel, specialized coolant formulations with enhanced lubricity may be necessary. These can reduce cutting forces by up to 25% compared to standard coolants.

Významné úvahy

Different materials present unique challenges in deep hole drilling. We need to adjust our approach based on what we’re working with.

Soft materials like aluminum can produce long, stringy chips that may wrap around the tool. Special chip breakers and higher coolant pressures typically solve this problem.

Hard materials like hardened steel or titanium create different concerns:

- Higher cutting forces

- Accelerated tool wear

- Greater heat generation

- More difficult chip formation

The material’s hardness and consistency directly impact the drilling parameters. For instance, stainless steel requires slower speeds and feeds than aluminum, with typical cutting speeds about 60-70% lower.

We’ve also found that composite materials require specialized tooling with unique geometries to prevent delamination and fiber pullout. Carbon fiber composites, for example, work best with diamond-coated tools that resist the abrasive nature of the material.

Common Challenges And Their Solutions

Deep hole drilling inevitably presents obstacles, but experienced machinists have developed effective solutions for most common issues.

Drill drift occurs when the drill veers off course during operation. We combat this by:

- Using pilot holes to establish direction

- Employing specialized guide bushings

- Starting with slower speeds until the drill is established

- Using vibration-dampening tool holders

Tool breakage represents another significant challenge. Prevention strategies include:

- Progressive pecking cycles for chip clearance

- Správny tool selection based on material

- Regular tool inspection for wear

- Maintaining consistent coolant pressure

Surface finish problems often stem from vibration or improper chip evacuation. Solutions include adjusting rezací parametre and ensuring proper tool support.

Heat management remains critical throughout the process. Excessive heat can cause material expansion that pinches the drill, leading to catastrophic failure. Proper coolant application and occasional “breathing” cycles allow heat dissipation in demanding applications.

Equipment And Technology

Deep hole drilling requires specialized equipment and advanced technology to achieve precise results. The right tools make all the difference in creating accurate holes with high depth-to-diameter ratios.

Specialized Machines And Dual Spindle Systems

When it comes to deep hole drilling, standard drilling equipment simply won’t cut it. Specialized machines are designed specifically to handle the unique challenges of deep hole applications.

Dual spindle systems are a game-changer in this field. These systems allow for simultaneous drilling from both ends of a workpiece, which significantly reduces production time. We’ve seen this approach cut drilling time by up to 50% in many applications!

The machines often feature:

- Rigid beds to minimize vibration

- High-pressure coolant systems

- Advanced chip evacuation mechanisms

- Specialized workholding fixtures

For extremely deep holes, gun drilling machines provide the stability needed for holes with depth-to-diameter ratios of 100:1 or even greater. These machines maintain the straightness and accuracy that’s critical in aerospace and defense applications.

Cutting Tools And Materials

Ten nástroje used in deep hole drilling are quite different from standard drill bits. Gun drills a BTA (Boring and Trepanning Association) tools are the most common types.

Gun drills feature:

- Single cutting edge design

- Internal coolant channels

- Special flute geometry for chip evacuation

BTA tools, on the other hand, use:

- Multiple cutting edges

- External coolant supply through the tool head

- Internal chip removal systems

The materials used for these tools need to withstand extreme conditions. We typically see:

- Karbid

- Coated carbide

- High-speed steel with special coatings

Tool life is critical in deep hole operations, with many manufacturers reporting that high-quality náradie z karbidu can last 2-3 times longer than standard options when used correctly.

Recent Technological Advancements

The field of deep hole drilling has seen impressive technological progress in recent years. Computer modeling now allows engineers to simulate drilling operations before cutting any material.

Coolant technology has also evolved, with new formulations that:

- Reduce friction and heat generation

- Improve chip evacuation

- Extend tool life by up to 40%

New coating technologies like PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) create super-hard surfaces on cutting tools. These coatings can increase tool life by 30-200% depending on the application!

Another exciting development is minimum quantity lubrication (MQL) systems that reduce environmental impact while maintaining cutting performance.

Automation And Precision Control Systems

Modern deep hole drilling relies heavily on automation and precise control systems. CNC (Computer Numerical Control) technology enables operators to program exact parameters for each drilling operation.

Real-time monitoring systems track:

- Spindle speed and torque

- Coolant pressure and flow

- Tool position and feed rate

- Vibration and temperature

When these parameters drift outside acceptable ranges, automated systems can make adjustments or stop operations to prevent damage.

Vision systems and in-process measurement tools verify hole quality without removing the workpiece from the machine. This integration of quality control into the production process has reduced rejection rates by up to 35% in many facilities.

Smart factory integration allows deep hole drilling machines to communicate with other production equipment, creating seamless workflows.

Budúce trendy a inovácie

The deep hole drilling landscape is rapidly evolving with exciting technological advancements that promise to transform precision engineering capabilities. These innovations are reshaping how industries approach complex drilling operations.

Emerging Technologies In Deep Hole Drilling

Automation is revolutionizing deep hole drilling processes in 2025. We’re seeing smart systems with real-time monitoring capabilities that can adjust drilling parameters automatically based on feedback data. This reduces human error and improves consistency.

AI-powered predictive maintenance is another game-changer. These systems can detect potential tool failures before they happen, saving companies thousands in downtime costs.

Digital twin technology creates virtual replicas of drilling operations. Engineers can simulate different scenarios without wasting materials or risking equipment damage.

High-precision sensors now measure hole straightness to micron-level accuracy during the drilling process. This immediate feedback allows for corrections that weren’t possible with traditional methods.

Robotics integration is increasing drill bit positioning precision and handling of workpieces, especially valuable for components requiring exceptional tolerances.

Industry Growth Projections

The deep hole drilling market is expected to grow at a CAGR of 6.8% through 2032. This growth is driven by increasing demand from aerospace, automotive, and medical device manufacturing sectors.

Aerospace applications lead market demand, with requirements for fuel system components and landing gear parts contributing significantly to industry expansion.

Medical device manufacturing represents the fastest-growing segment, with specialized drilling needs for surgical instruments and implantable devices.

The Asia-Pacific region shows the highest growth potential due to rapid industrialization in countries like China and India. These markets are investing heavily in manufacturing capabilities requiring precision drilling.

North America maintains a strong market position thanks to its aerospace and defense industries. Their need for high-precision components drives continuous innovation in drilling technologies.

Úvahy o udržateľnosti

Energy efficiency has become a priority in modern deep hole drilling. New electric drilling systems use up to 40% less energy than traditional hydraulic systems while maintaining or improving performance.

Coolant recycling technologies are reducing fluid waste by up to 85%. These closed-loop systems filter and reuse cutting fluids, decreasing environmental impact and operating costs.

Dry drilling techniques are emerging for certain applications. These methods eliminate the need for cutting fluids entirely, addressing environmental concerns related to fluid disposal.

Tool coating innovations are extending drill bit life by 2-3 times. This reduces material waste and the frequency of replacements.

Manufacturers are increasingly adopting ISO 14001 environmental management standards. We’re seeing this certification become a competitive advantage in the drilling services market.

New Materials And Applications

Advanced carbide composites are revolutionizing drill bit durability. These materials withstand higher temperatures and resist wear better than traditional options.

Nano-coatings applied to drill bits reduce friction by up to 30%. This allows for faster drilling speeds and cooler operation even in challenging materials.

Exotic alloy drilling capabilities have expanded significantly. Materials like Inconel, titanium alloys, and specialized stainless steels that were once difficult to drill can now be processed with higher precision.

The electric vehicle industry has created new applications for deep hole drilling. Battery cooling channels and motor shaft components require the extreme precision that only advanced deep hole drilling can provide.

Miniaturization in electronics has pushed the boundaries of micro-drilling. Holes with diameters below 0.5mm and depth-to-diameter ratios exceeding 50:1 are now achievable with specialized equipment.