Have you ever wondered what makes a screw or bolt work so well? It’s all about the threads. Today, we’re diving into the intriguing world of internal and external threads. Internal threads are cut on the inside of a hole, while external threads are cut on the outside of a cylinder or cone. This key difference is what determines how components fit together and stay connected.

Why do these small details matter so much? Think about the last time you tightened a bolt on your bike or assembled a piece of furniture. It’s those precise spirals—either on the inside or outside—that ensure your items not only fit snugly but also function safely. Understanding these threads can help us choose the right components for various tasks, whether it’s ensuring leak-proof connections or supporting heavy loads.

In the engineering world, threads fall into three main classes: 1A, 2A, and 3A for external threads, and 1B, 2B, and 3B for internal threads. These classes dictate the level of fit between parts. With this knowledge, we can decide which type to use in different situations, ensuring reliability and performance. Let’s explore how these tiny yet powerful features keep our world spinning smoothly.

Understanding The Basics

Let’s explore the ins and outs of threads. We’ll look at what threads are and why we need them, define internal and external threads, learn how to identify different thread types, and understand key terms related to threading.

What Are Threads And Why Do We Need Them?

Threads are ridges wrapped around a cylinder or cone. They’re used in fasteners like screws and bolts to hold things together. Imagine fixing a bookshelf with screws—without threads, that wouldn’t work! Threads help in creating mechanical connections that are both strong and easily detachable. Our world relies on threads more than we might think, from furniture assembly to industrial machinery.

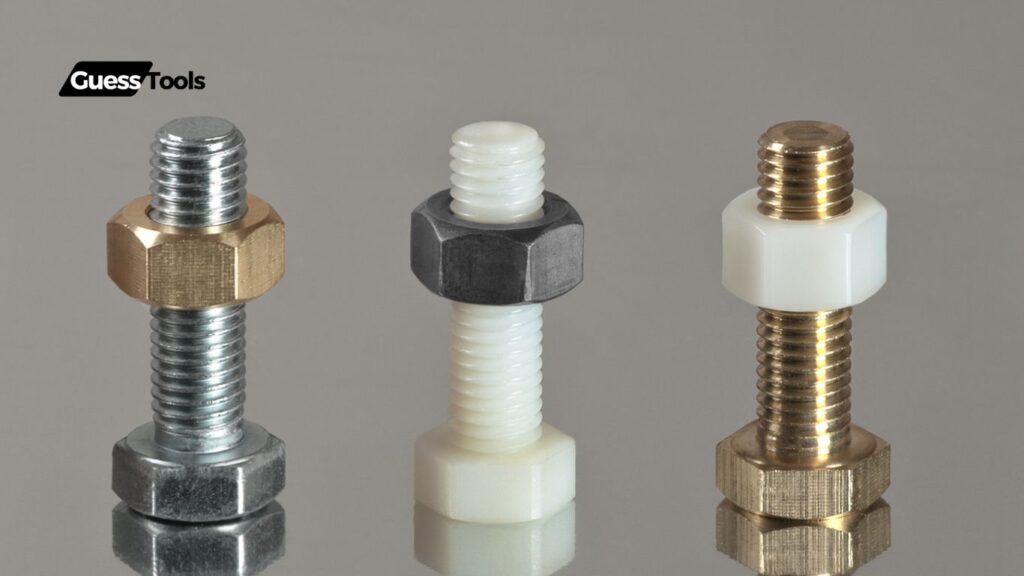

Internal Threads vs External Threads: Simple Definitions

Internal threads, or female threads, are found inside a hole. They’re designed to mate with external threads, or male threads, which are on the outside of a part, like on a bolt or screw. Picture a nut and a bolt—the nut has internal threads and the bolt has external threads. These two types work together to form a secure connection. The basic idea is that one fits inside the other, allowing for a firm assembly.

Visual Guide To Identifying Thread Types

Identifying thread types can be easier if we know what to look for. External threads are visible on the outside of parts like bolts. Internal threads might need a closer look inside nuts or holes. A visual check often involves looking at the shape and size of the ridges. The thread count and pitch (space between ridges) are also key. Sometimes, using a thread gauge can help determine the exact type needed.

Common Terminology You Need To Know

It’s helpful to know some key terms when dealing with threads. Major diameter is the largest diameter of the thread. It appears on the crest of both external and internal threads. Minor diameter is the smallest diameter, found at the root of the threads. Pitch refers to the distance between threads. Knowing these terms helps us better understand thread specifications and choose the right ones for any task.

Practical Applications

Threads are essential to many things in both everyday life and specialized industries. Internal threads like in nuts provide secure holding. External threads can be found on bolts and screws, providing easy attachment. These threads are crucial in several industries like automotive and aerospace, ensuring efficient fastening and assembly.

Where You’ll Find Internal Threads In Everyday Items

We often encounter internal threads in items we use daily. For instance, the nuts we use help you fasten screws and bolts securely. They are common in furniture assembly, where they connect different parts tightly.

Another familiar example is a threaded cap on a water bottle, which uses internal threading to screw onto the bottle neck. Internal threads also play a vital role in plumbing, securing pipes with fittings to prevent leaks. Each of these applications shows how internal threads contribute to sturdiness and reliability in our everyday tools and gadgets.

Common Uses Of External Threads

Let’s talk about external threads. You’ll find them on bolts and screws, making them vital in construction and repairs. Imagine trying to assemble furniture without them—it would simply fall apart! These threads also help in household items like light bulbs that screw into fixtures.

In the automotive industry, external threads feature prominently in car engines and other assemblies. They support heavy loads and ensure that parts stay well-fitted and safe. Their design allows for secure connections and easy disconnection whenever necessary. Whether it’s fixing a table leg or sealing a container, external threads are everywhere, offering precision and versatility.

Industry-Specific Applications

Certain industries heavily rely on both internal and external threads for specialized purposes. In the automotive sector, we use threaded fasteners in engines, suspensions, and wheels, ensuring vehicles are built to last. These fasteners make assembly efficient and allow for easy repairs or replacements.

In aerospace, threads hold together high-stress parts like engine components and wings. They have to withstand extreme conditions and high pressure. In manufacturing, threaded applications enable assembly lines to work smoothly, providing products that are safe and reliable.

The widespread use of threaded fasteners across these industries shows just how important and adaptable threads are to creating durable products.

Choosing Between Internal And External Threads

When deciding between internal and external threads, it’s important to focus on factors like application requirements and material compatibility. Assessing the specific needs of your project and avoiding common mistakes can ensure a strong, reliable connection.

Key Factors In Thread Selection

When choosing between internal and external threads, we need to focus on several key factors to ensure a secure and efficient connection. The first thing to consider is material compatibility. It is important to match the thread type with materials that suit the intended application, preventing corrosion or wear. Another critical factor is thread pitch and depth. These must be appropriate for the load and forces expected in the application to avoid failure.

Strength requirements are also essential. The strength of the joint can be influenced by the thread type. Internal threads often provide better sealing and can be more reliable for holding materials together. Evaluating how compatible and strong the threads need to be is vital. Considering these aspects will help avoid errors and achieve what the project needs.

Making The Right Choice For Your Project

Deciding on the right thread type for a specific project involves careful assessment of project specifics. We must first reflect on how the threads will be used. For example, internal threads are commonly inside nuts or pipe fittings. They are great when reliable sealing or holding capabilities are needed. External threads, like those on bolts, often work well in applications requiring easy installation or frequent removal.

For specific dimensions, existing standards, like the Metric system’s 6H and 6g thread tolerances, must be adhered to. This ensures interchangeability and proper fit across different items. Taking into account the assembly processes or environments, such as exposure to moisture, can also influence our decision. By carefully weighing these considerations, we can choose the most suitable thread type for any project needs.

Common Pitfalls To Avoid

When working with threads, there are common mistakes that we must steer clear of. One major issue is mismatching thread types. Mismatched threads can lead to weak connections, risking performance or even failure. For instance, using a 1A external thread with a 3B internal thread could compromise functionality.

Another problem is failing to check thread engagement. Proper engagement is crucial for strong and reliable joints. If the threads do not fit correctly, it might cause problems later. Additionally, neglecting to consider material specific properties such as its elasticity or hardness can lead to premature wear or damage. Avoiding these pitfalls ensures durable and successful application of the chosen threads.

Technical Specifications And Standards

When it comes to threading, understanding technical specifications is key. It involves many dimensions and standards that ensure parts fit together. These specifications include classifications, pitch, diameter, and much more. Let’s dive into the major aspects that shape thread design and use.

Thread Classifications And Standards

Threads are classified into specific classes and standards to ensure compatibility. Unified Thread Standard (UTS) is commonly used in the U.S., which categorizes threads into classes such as 1A/1B, 2A/2B, and 3A/3B.

- Class 1: Loose fit, ideal for easy assembly.

- Class 2: Standard fit, used in most applications.

- Class 3: Tight fit, precision applications where accuracy is crucial.

These classes determine tolerance, impacting how parts fit together. Metric threads, on the other hand, are identified with a series like M10x1.5, representing the nominal diameter and pitch.

Metric vs Imperial

Threads can be specified in metric or imperial systems. Metric threads are measured in millimeters and are widely used internationally. For instance, in metric threads, you’ll often see specifications like M8x1.25, where ‘M’ means metric, ‘8’ is the nominal diameter, and ‘1.25’ is the thread pitch.

Imperial threads, including UNC (Unified National Coarse) and UNF (Unified National Fine), use inches. An example is #10-32, where ‘#10′ indicates size and ’32’ is the number of threads per inch.

We often see metric threads described using nominal and pitch diameter, while imperial threads rely on thread count per inch and major diameter.

Special Thread Types (NPT, UNC, UNF)

National Pipe Thread (NPT), UNC, and UNF are common thread types with specific uses. NPT threads are tapered, providing a seal in piping systems via a tightening process that compresses threads. This makes them ideal for plumbing.

UNC and UNF threads are part of the Unified Thread Standard. UNC has a coarser pitch than UNF, making it suitable for softer materials while UNF is preferred for stronger materials and precise applications. These threads ensure that parts remain secure under different conditions, with various allowances and tolerances affecting fit and function.

Understanding Thread Pitch And Diameter

Thread pitch and diameter are crucial for thread specification. The pitch is the distance between threads, while the diameter is from crest to crest. Key sizes include major diameter, minor diameter, and pitch diameter, all affecting fit and strength.

When understanding thread fit, the pitch diameter is vital as it controls crucial contact points of the thread. Lead, another dimension, signifies the distance a nut or bolt travels with one full turn, which is significant in multi-start threads.

Tolerance And Fit Considerations

Tolerance and fit are essential to ensure proper functionality. Different fits determine how easily components slide or secure. Class 1, 2, and 3 are key fit classes in unified threads, with the main focus on allowances and tightness.

For metric threads, fit classes like 6H for internal threads and 6g for external threads are standard. A proper allowance ensures components don’t bind when assembled, affecting performance and longevity. By tailoring tolerance and fit, engineers can optimize mechanical function and durability.

In summary, understanding these specifications helps us ensure that machine parts align correctly, are safe to use, and perform reliably in their respective applications. The technicalities may seem complex, but they form the basis of a well-functioning mechanical system.

Manufacturing And Machining

When we think about threading in manufacturing, it is crucial to understand how internal and external threads are crafted. Different machining techniques are employed to ensure precision and functionality. Let’s explore the various methods used to create these threads, focusing on practical aspects like tapping processes, thread milling, and quality control.

Methods For Creating Internal Threads

Internal threads are typically machined using taps or thread milling. Tapping involves inserting a tap into a pre-drilled hole, such as a blind or through hole, to cut threads. This method is efficient and works well for creating threads with high thread engagement. However, using taps in blind holes requires precision to avoid damaging the tap.

Thread milling, on the other hand, is a more advanced method. A CNC machine moves a cutter in a helical path to produce threads. This approach allows for adjustments in thread engagement length and offers flexibility for different thread sizes. Using CNC machining for internal threads also improves accuracy and surface finish compared to traditional tapping methods.

Tapping Processes

Tapping is a well-known technique that many machinists rely on. It uses a thread-making tool called a tap to cut threads inside holes. For internal threads, taps can be hand-operated or machine-driven. The process is straightforward but requires attention to detail, especially in blind holes where over-cutting can occur.

Two main types of taps exist: hand taps and machine taps. The former is used with a manual tap wrench, while the latter is used with power tools. The choice between hand taps and machine taps often depends on the material being threaded and the hole type. It’s a widely favored method due to its straightforward execution and cost-effectiveness.

Thread Milling

Thread milling is an alternative to tapping. It involves rotating a cutting tool around the inside of the material to form the thread. This method is ideal for cutting threads into hard materials or larger diameters, where taps might not perform as well. Thread milling provides flexibility and can create threads with varying diameters using the same tool.

With CNC machines, thread milling offers greater control over thread depth and pitch. This flexibility leads to a smoother finish and allows for precise thread engagement control. It’s particularly useful in cases where the internal threading needs to meet strict tolerance requirements.

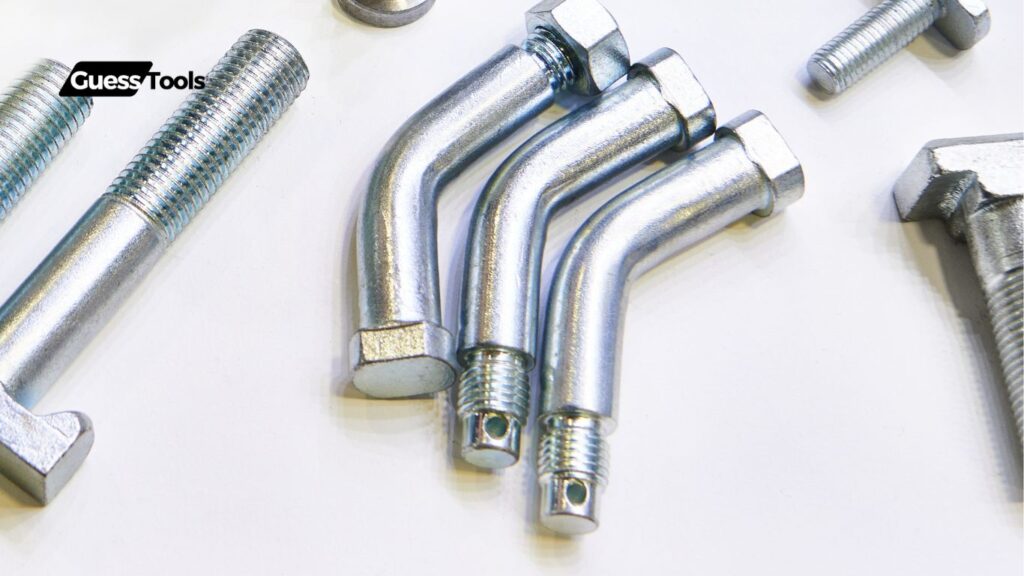

Techniques For External Thread Production

External threads are usually created on the outer surface of cylindrical components such as bolts or screws. The common methods for producing these threads include turning, thread rolling, and thread grinding. In turning, a machine uses a cutting tool to remove material and form threads.

Thread rolling is a fascinating method that doesn’t remove material. Instead, it displaces it, making the threads stronger and more durable. Thread grinding is employed for precision threads and involves using a grinding wheel. Each method depends on the application requirements, including thread size and material hardness.

Quality Control And Inspection Methods

Quality control in threading processes ensures that the threads meet specifications and function as needed. Measuring thread size, engagement length, and alignment are critical aspects of quality inspection. Tools like thread gauges and coordinate measuring machines (CMMs) are used to verify dimensions and ensure consistent quality.

Regular inspection during and after production is essential. This process helps catch irregularities before they can cause issues in assembly or during product use. By investing in thorough quality control, manufacturers can minimize defects, reduce waste, and ensure high standards in their threading operations.

Maintenance And Troubleshooting

When it comes to ensuring the longevity and performance of threads, it’s vital to be proactive with maintenance and aware of common issues. Knowing when to repair versus replace and which tools to use for inspection can make a big difference.

Common Thread Problems And Solutions

Threads might face wear and tear over time, leading to frequent issues. One common problem is cross-threading, which occurs when threads are misaligned during assembly. To fix this, we should always start threading by hand before using tools.

Corrosion can also affect threads, especially in humid environments. Using anti-corrosion coatings on metal threads can help. For damaged threads, tools like thread repair kits or helicoils can restore them. Regular inspections can catch these issues early, preventing larger problems down the road.

Proper Thread Maintenance

Maintaining threads involves regular cleaning and lubrication. Cleaning removes dirt and debris that can cause sealing performance issues. A soft brush or cloth works well without damaging the threads.

Using lubricants, such as thread sealant or anti-seize compounds, goes a long way in ensuring smooth operation. This is crucial during assembly and disassembly, making the process easier and preventing wear. Inspecting threads for any visible signs of damage should be part of routine maintenance.

When To Repair vs. Replace

Determining whether to repair or replace threads can save us time and money. Minor damage like shallow scratches can often be repaired using thread taps or dies. These tools help to clean up the threads and restore their shape.

If the damage is severe, with stripped or broken threads, replacement might be necessary. Replacement ensures safety and reliability, especially in applications that experience high stress. Understanding when to choose either option keeps our operations running smoothly and safely.

Tools And Techniques For Thread Inspection

Inspecting threads regularly is important to catch potential issues before they become serious. We can use tools like thread gauges to check the accuracy and wear of the threads. These tools help ensure threads are within the acceptable tolerance levels.

Visual inspections can also be valuable. Look for any signs of distortion or wear. Using a magnifying glass can reveal small imperfections not visible to the naked eye. Staying diligent with these inspections helps in identifying problems early, allowing for quick correction and reduced downtime in operations.

Advanced Considerations

When thinking about internal and external threads, there are several advanced factors to keep in mind. These include selecting materials compatible with specific applications, considering coatings that enhance performance, understanding uses in high-performance environments, and staying updated on future trends.

Material Selection And Compatibility

Choosing the right material for threads is crucial. We must consider the application’s environment and requirements. Threads made from stainless steel offer great corrosion resistance, which is important where moisture is a concern. Titanium threads are another option, providing high strength for aerospace applications. It’s about balancing strength and durability against cost.

Material compatibility is also essential. When joining two materials, we must choose options that prevent issues like galvanic corrosion. Mixing metals, such as aluminum and steel, may cause problems unless precautions are taken. Understanding these factors helps us create longer-lasting and effective threaded connections.

Specialized Coating Options

Coatings can play an important role in enhancing thread performance. Zinc plating is a popular choice, offering protection against rust and corrosion. For environments exposed to high temperatures, ceramic coatings can improve heat resistance.

There are also PTFE coatings, which reduce friction. This is especially beneficial for parts that see constant motion, as it minimizes wear. By choosing the right coating, we can significantly extend the lifespan and functionality of our threaded components.

High-Performance Applications

High-performance settings demand more from threads. In the automotive and aerospace industries, threads face extreme stresses and heat. Using the right thread forms and materials here is paramount. Metric fine threads, for example, provide better clamping forces due to higher tension relief.

In environments where precision and reliability matter, threads must undergo rigorous testing. Surface treatments and precise machining ensure that they can handle unique pressures. High-performance threads deliver reliability under challenging conditions, making them essential in these industries.

Future Trends In Thread Technology

What’s in store for the future of thread technology? We see trends moving towards self-healing materials that minimize maintenance needs. Smart threads, capable of sending performance data, might not be far off either. By integrating nanotechnology, threads could see enhancements in strength and durability.

Sustainability is another trend, prompting innovation in recyclable and environmentally-friendly materials. The future brings exciting possibilities for thread technology, where improvements can lead to better efficiency and longer life spans for vital components.

Resources And References

When dealing with internal and external threads, having the right resources can make a big difference. We will explore industry standards, reliable calculation tools, and places to find more information to help us stay ahead. A glossary will also be provided to clarify common terms we may encounter.

Industry Standards And Specifications

Navigating through thread standards is essential for precision and compatibility. ISO standards, like ISO 68 for thread profiles, are widely recognized. ANSI/ASME standards provide guidelines, such as B1.1 for unified threads. These standards ensure interoperability across different tools and components.

Additionally, using compliant tools that meet these standards ensures that threads function reliably. For anyone involved in manufacturing or engineering, understanding these standards helps maintain quality control and prevents errors in production processes.

Useful Calculation Tools

How can we ensure our threads will fit perfectly? Calculation tools can be our best friends here. Tools like screw thread calculators are invaluable for finding dimensions and tolerances quickly.

Some calculators offer features like pitch, lead, and depth of thread measurements. Software options, like MACHINIST CALC PRO, even provide tapered thread calculations. With these tools, we minimize mistakes and optimize our designs efficiently.

Where To Find Additional Information

Looking for more in-depth knowledge about threads? Books such as “Machinery’s Handbook” offer detailed insight. Online resources like forums, including Stack Overflow, provide practical advice and real-life solutions from industry professionals.

Websites from tools and fastener manufacturers often list detailed specifications and guidelines. Additionally, courses from platforms like Coursera or Udemy are valuable for gaining a comprehensive understanding through structured lessons.

Glossary Of Terms

Understanding thread-related terminology is important for effective communication. Here are some key terms:

- Pitch: The distance between corresponding points on adjacent threads.

- Lead: For a screw, it’s the distance a nut moves with one full rotation.

- TPI (Threads Per Inch): The number of threads in one inch.

- Taper: Refers to threads that gradually decrease in diameter, often seen in pipe threads.

Having this glossary aids our comprehension and ensures clear communication in technical discussions.