Choosing the right carbide inserts can feel overwhelming, especially if you’re new to machining. We understand this challenge and want to help you navigate through the important factors to consider. The best carbide insert for your project depends on the material you’re cutting, the type of operation you’re performing, and your specific requirements for surface finish and tool life.

Have you ever wondered why some inserts wear out quickly while others last for ages? It’s not just about the brand name or price tag. The geometry, coating, grade, and chip breaker design all play crucial roles in how an insert performs. We’ve seen many machinists struggle with poor results simply because they focused on the wrong parameters when selecting their tooling.

When you choose the right carbide insert, you’ll notice immediate improvements in your machining efficiency, surface quality, and overall productivity. That’s why we created this guide – to walk you through the essential considerations that will help you make informed decisions about your tooling needs. Let’s make your next machining project more successful by selecting the perfect carbide insert for the job!

Understanding the Basics of Carbide Inserts

Carbide inserts are essential cutting tools that revolutionize metalworking operations. They offer exceptional hardness, heat resistance, and durability that traditional cutting tools simply can’t match.

Definition and Importance in Machining Operations

Carbide inserts are small, replaceable cutting tips made from tungsten carbide and other compounds. They’re designed to attach to toolholders for various machining operations like turning, milling, and boring. These inserts are indexable, meaning you can rotate or flip them to use multiple cutting edges before replacement.

Why are they so important? Simply put, carbide inserts allow for:

- Higher cutting speeds than traditional tools

- Better heat resistance during high-speed operations

- Consistent performance across different materials

- Precision machining of tough materials like cast iron, steel, and high-temperature alloys

We’ve found that most shops use carbide inserts for about 80% of their metalworking applications due to their versatility and reliability.

How Proper Selection Impacts Efficiency, Tool Life, and Finished Product Quality

Choosing the right carbide insert dramatically affects your machining success. The wrong insert can lead to poor surface finish, excessive tool wear, and wasted materials.

Tool life extends significantly with proper selection. An appropriate carbide grade and geometry can last 2-5 times longer than an incorrect choice. This means fewer changeovers and reduced downtime.

Machining efficiency improves through:

- Faster cutting speeds

- Better chip control

- Reduced cutting forces

The quality of finished products depends heavily on insert selection. Proper inserts produce better surface finishes, tighter tolerances, and fewer defects.

We recommend considering your specific workpiece material, cutting parameters, and toolholder compatibility when selecting inserts. These factors form the foundation for successful machining operations.

Matching Workpiece Materials to Carbide Insert Types

Different materials require specific carbide insert types to achieve optimal cutting performance. The right match between your workpiece material and insert can dramatically improve tool life, surface finish quality, and overall machining efficiency.

Steel and Stainless Steel Compatibility

When machining steel and stainless steel, we recommend using coated carbide inserts with positive rake angles. For general steel applications, P-grade carbide inserts work best, with P10-P30 being ideal for most steel machining operations.

Stainless steel presents unique challenges due to its work-hardening properties. Here, we suggest:

- PVD-coated carbide inserts for better edge strength

- Inserts with chip breakers designed specifically for stainless steel

- CVD aluminum oxide coatings for high-temperature resistance

Sharp cutting edges help reduce work hardening, while the right coating prevents built-up edge formation. For high-speed machining of steel, try inserts with TiAlN coatings that maintain hardness at elevated temperatures.

Cast Iron Applications

Cast iron machining benefits from K-grade carbide inserts, particularly K10-K30 ranges. These inserts are designed to handle the abrasive nature of cast iron while preventing edge chipping.

For gray cast iron, we’ve found that:

- Uncoated carbide inserts often perform well

- Negative rake angles improve tool stability

- Larger nose radius designs handle the brittle nature better

Ductile cast iron requires:

- TiN or Al₂O₃ coated inserts

- Medium-positive rake angles

- Good chip evacuation features

The irregular surfaces and inclusions in cast iron demand inserts with excellent impact resistance. A strong cutting edge geometry with adequate support behind the edge prevents premature tool failure during interrupted cuts.

Aluminum and Non-Ferrous Metals Considerations

Aluminum and non-ferrous metals require N-grade carbide inserts with polished surfaces to prevent material buildup. For these softer materials, we suggest:

- Highly positive rake angles (15-20°) to reduce cutting forces

- Polished flute surfaces to improve chip evacuation

- Diamond-coated inserts for high-silicon aluminum alloys

When machining copper alloys, consider:

- Inserts with larger clearance angles

- Sharp cutting edges to reduce burr formation

- Diamond-polished surfaces to prevent sticking

For high-speed aluminum machining, we’ve had great success with PCD (polycrystalline diamond) inserts. Though more expensive initially, they often deliver better overall economics through extended tool life and superior surface finish.

Superalloy and Hardened Material Requirements

Superalloys and hardened materials present the greatest challenge, requiring S-grade and H-grade carbide inserts respectively. For these tough materials:

Superalloys (Inconel, Hastelloy, etc.):

- Use S-grade carbide with multi-layer PVD coatings

- Select smaller depths of cut with rigid tooling setups

- Consider round insert geometries for improved edge strength

Hardened materials (>45 HRC):

- H-grade carbide inserts with CBN (cubic boron nitride) coating

- Negative rake angles for edge strength

- Small nose radius for precision finishing

Heat-resistant superalloys often cause rapid tool wear. We recommend inserts with specialized cobalt-enriched substrates that maintain hardness at high temperatures. For optimal results, pair these inserts with appropriate cutting speeds (typically 50-70% lower than those used for standard steels).

Critical Selection Factors: Insert Geometry and Shape

The shape and geometry of carbide inserts play a crucial role in determining cutting performance. Different shapes offer varying levels of strength, cutting edge options, and application suitability that directly impact your machining results.

Round Inserts: Benefits for Heavy Cutting and Smooth Finishes

Round carbide inserts are excellent choices for heavy-duty cutting operations. Their circular shape distributes cutting forces evenly around the entire insert, making them incredibly strong and resistant to breakage.

What makes round inserts special? They have an infinite number of cutting edges! When one section dulls, you can simply rotate the insert slightly to expose a fresh cutting edge.

Round inserts are particularly good for:

- Roughing operations on tough materials

- High feed rate machining

- Creating smooth curved surfaces

- Applications requiring gradual entry into workpieces

The large nose radius of round inserts produces excellent surface finishes. We’ve found that round inserts typically last 30-40% longer than other shapes when used in appropriate applications.

Square and Triangular Inserts: Multiple Cutting Edge Advantages

Square and triangular inserts offer cost-effective solutions with multiple cutting edges. A square insert provides 8 potential cutting edges (4 corners × 2 sides), while triangular inserts offer 6 cutting edges (3 corners × 2 sides).

Why choose these shapes? Economy and versatility.

Square inserts work well for:

- Medium to heavy cutting

- 90° shoulder milling

- Facing operations

- General-purpose machining

Triangular inserts excel at:

- Light to medium cutting

- Higher feed rates

- Spaces with limited clearance

- Finishing operations on contoured surfaces

The sharp corners make them ideal for creating precise features. We recommend square inserts when you need strength and stability, while triangular inserts offer better access to tight spots.

Diamond and Trigon Inserts: Precision Finishing Applications

Diamond (rhombic) and trigon inserts are specialized shapes designed for precision work. Diamond inserts feature an 80° or 55° included angle, creating a pointed tip perfect for detailed work.

Trigon inserts, with their unique 60° corners, bridge the gap between triangular and round inserts.

Best applications for diamond inserts:

- Precision groove cutting

- Copy milling

- Fine detail work

- Thread turning

Trigon inserts excel at:

- Profiling operations

- Medium finishing cuts

- Semi-roughing operations

- Machining with limited power

The acute angles of diamond inserts allow access to tight spaces while minimizing cutting forces. We’ve seen trigon inserts reduce vibration by up to 25% compared to triangular inserts in similar applications.

How Shape Selection Affects Cutting Performance

The shape you choose directly impacts three critical factors: strength, access, and economy.

Strength hierarchy (from strongest to weakest):

- Round

- Square

- Trigon

- Triangular

- Diamond

Stronger shapes can handle higher cutting forces but offer less precision. Weaker shapes provide better access but may break under heavy loads.

Your approach angle is also affected by insert shape. Round inserts allow gradual engagement, reducing shock. Diamond inserts create more concentrated cutting forces at the point.

Insert shape influences chip formation and evacuation too. Wide-angled inserts (like squares) create thicker chips while diamond shapes produce narrower chips that evacuate more easily.

When selecting, consider:

- What’s the operation type? (roughing vs. finishing)

- How much cutting force will be applied?

- Do you need to access tight spaces?

- How important is surface finish quality?

Understanding Carbide Grades and Coatings

Carbide inserts come in various grades and coatings that significantly impact their performance in different applications. Choosing the right combination can mean the difference between an excellent finish and a failed operation.

CVD Coatings: High-Speed Applications and Wear Resistance

Chemical Vapor Deposition (CVD) coatings are perfect when you need durability at high cutting speeds. These coatings are applied at temperatures between 900-1050°C, creating a thick, strongly bonded layer.

Common CVD coatings include:

- TiC (Titanium Carbide): Offers excellent wear resistance

- TiN (Titanium Nitride): Provides good all-around protection

- Al2O3 (Aluminum Oxide): Creates a thermal barrier that protects against heat

CVD coatings excel in high-speed machining of cast iron, carbon steel, and alloy steels. We’ve found they typically increase tool life by 200-300% compared to uncoated inserts when used for continuous cutting operations.

The thick coating (usually 5-15 μm) makes these inserts ideal for rough machining where the priority is removing material quickly rather than achieving perfect surface finish.

PVD Coatings: Applications for Stainless Steel and Exotic Materials

Physical Vapor Deposition (PVD) coatings are applied at lower temperatures (400-600°C) and create thinner, smoother layers. This makes them perfect for sharper cutting edges and more precise work.

Key benefits of PVD coatings:

- Greater edge strength

- Better resistance to chipping

- Improved performance on sticky materials

When working with stainless steel, titanium, or high-temperature alloys, PVD-coated inserts typically outperform other options. The coating reduces built-up edge formation that commonly occurs with these materials.

Modern PVD coatings like TiAlN (Titanium Aluminum Nitride) and AlCrN (Aluminum Chromium Nitride) can withstand temperatures up to 900°C, making them suitable for dry machining applications. Their thinner coating (1-4 μm) preserves cutting edge sharpness while still providing good wear protection.

Uncoated Options: When and Why to Use Them

Uncoated carbide inserts still have an important place in machining operations. They’re often the best choice for non-ferrous materials like aluminum, brass, and copper.

Situations where uncoated inserts shine:

- Machining soft, non-abrasive materials

- Applications requiring very sharp cutting edges

- When chip welding is a concern with coated tools

Uncoated inserts are typically classified using the ANSI system with grades like C-2 (for general purpose) through C-8 (for heavy roughing). The higher the number, the tougher but less wear-resistant the insert.

We recommend starting with uncoated options when machining aluminum alloys, as coatings can sometimes cause aluminum to stick to the tool. Uncoated inserts are also more cost-effective for short production runs where tool life isn’t a major concern.

Latest Advancements in Coating Technology

The carbide insert industry continues to evolve with exciting new coating technologies that push performance boundaries.

Recent innovations include:

- Nano-layered coatings: Alternating ultra-thin layers of different materials for improved toughness

- Diamond-like carbon (DLC): Exceptional hardness with low friction for machining graphite and composites

- Hybrid coatings: Combining CVD and PVD processes for optimal performance

Multi-layer coatings now often feature 10+ distinct layers, each optimized for specific properties. For example, a modern insert might have a tough TiCN base layer, an Al2O3 heat barrier in the middle, and a low-friction TiN top layer.

Manufacturers like Sandvik and Kennametal have developed proprietary coating technologies that can extend tool life by up to 400% in challenging applications. These advanced coatings often feature specialized elements like zirconium or hafnium to enhance specific properties.

Application-Specific Selection Guide

Different machining operations demand specific insert characteristics to achieve optimal results. When selecting carbide inserts, you need to consider the unique challenges presented by turning, milling, and drilling applications.

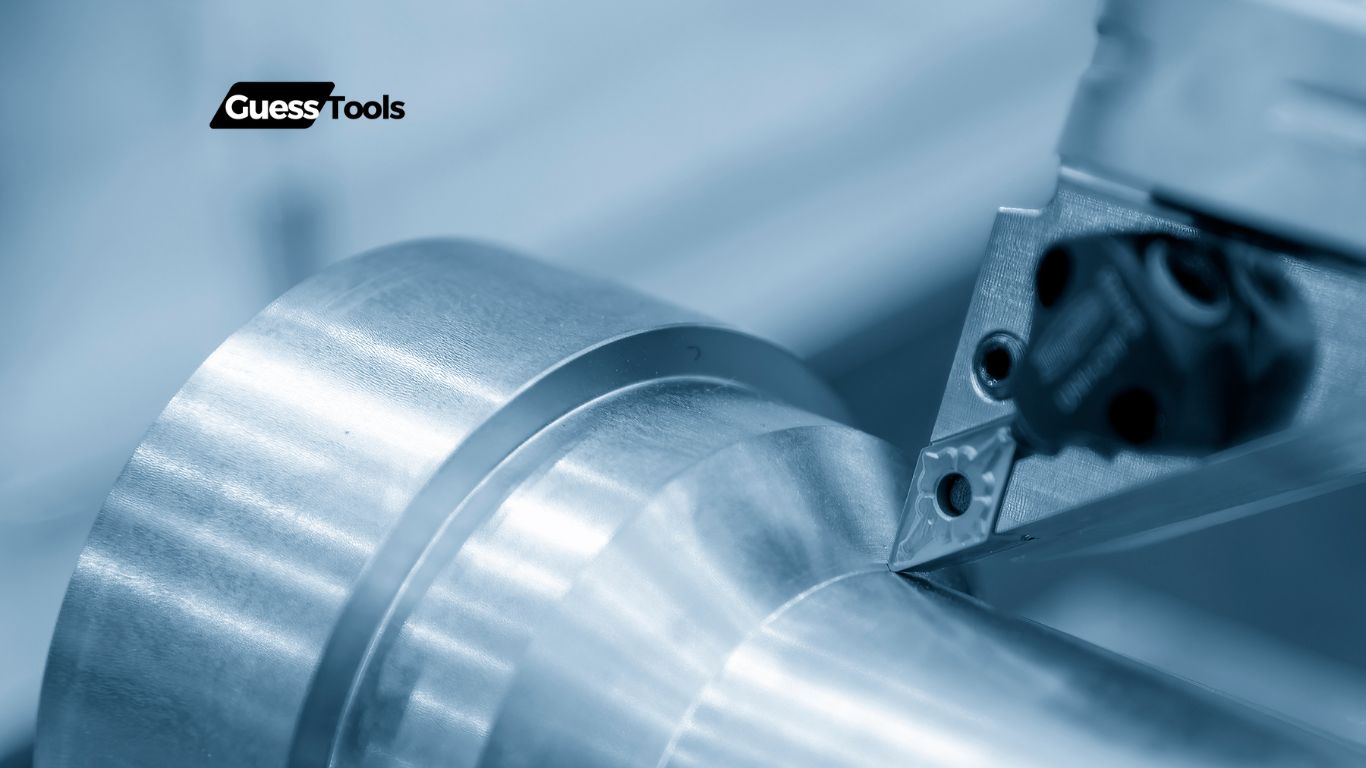

Turning Operations: Thermal Stability and Chip Evacuation

When machining in turning operations, heat management is crucial. Choose inserts with excellent thermal stability to prevent premature tool wear and failure.

Key considerations for turning:

- Insert geometry: Positive rake angles reduce cutting forces and heat generation

- Chip breaker design: Select geometries that form manageable chips to prevent tangling

- Coating type: TiAlN coatings excel in high-temperature turning applications

For continuous turning, we recommend inserts with rounded edges to resist crater wear. When turning tough materials like stainless steel, coolant-through systems can dramatically improve chip evacuation and extend tool life.

Heat buildup is your enemy in turning operations! PVD-coated carbide inserts typically perform better for finishing operations, while CVD coatings handle roughing tasks more effectively.

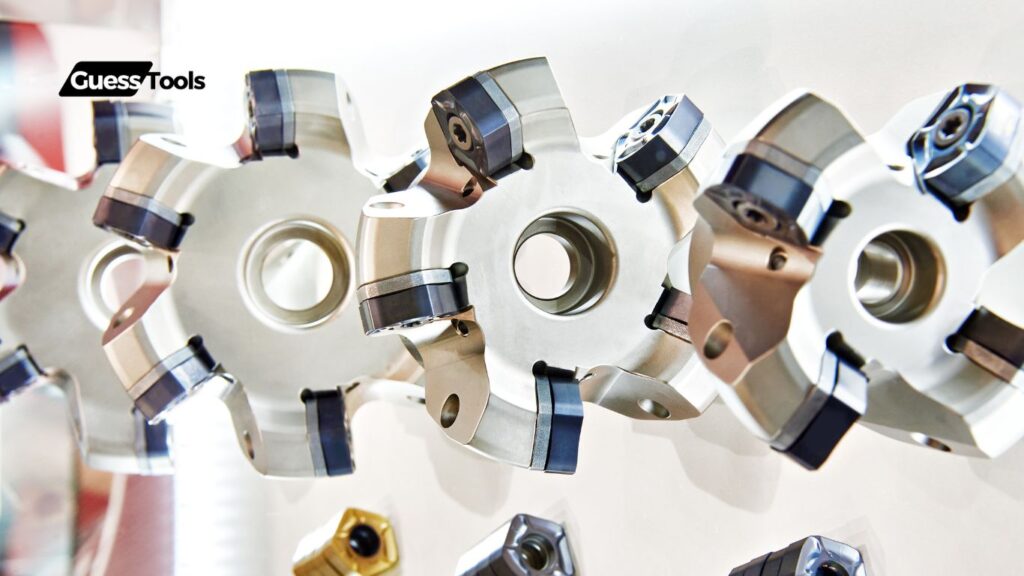

Milling Requirements: Handling Interrupted Cuts

Milling operations subject inserts to repeated impact forces and temperature fluctuations. Your inserts must be tough enough to withstand these conditions.

Optimal milling insert features:

- Thicker inserts (>3mm) for stability during heavy cuts

- Positive rake angles to reduce cutting forces

- Corner radius matching your finish requirements

When facing interrupted cuts, we suggest carbide grades with higher cobalt content (>10%) for improved toughness. Face milling typically benefits from round inserts that distribute cutting forces more evenly.

High-feed milling operations require inserts with specialized geometries that can handle the increased chip load. Look for inserts with “HF” designations in their coding for these applications.

Don’t forget about cutter balance! Even the best inserts won’t perform well in an unbalanced tool assembly, especially at high RPMs.

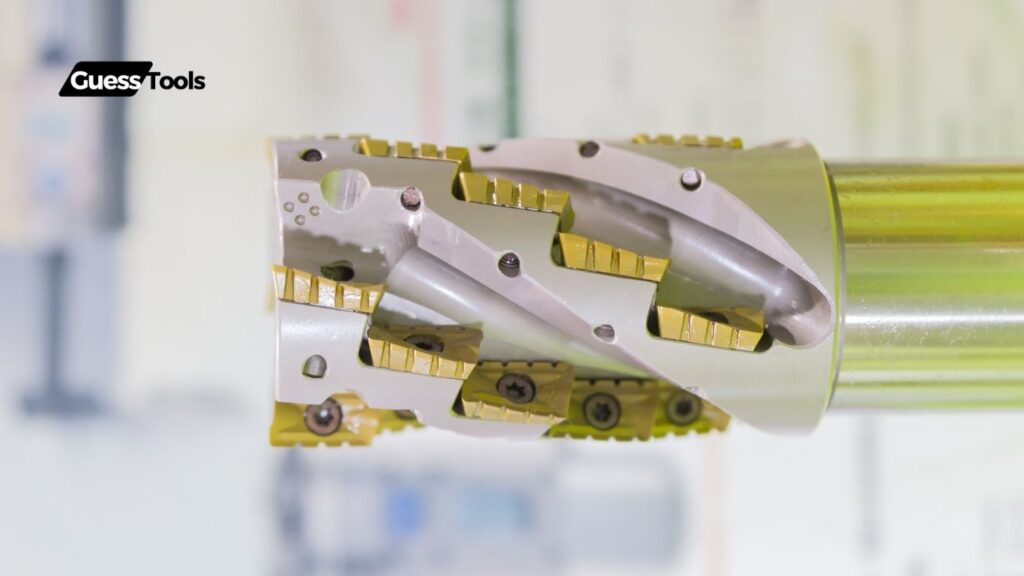

Drilling Considerations: Through-Coolant Capabilities

Drilling presents unique challenges with chip evacuation and heat buildup at the cutting zone. Through-coolant inserts are often essential for deeper holes.

Critical drilling insert factors:

- Point geometry matches material (sharper for aluminum, more robust for steel)

- Coolant channel design for effective chip evacuation

- Coating type suitable for the workpiece material

We’ve found that inserts with TiAlN coatings excel in drilling applications due to their high-temperature stability and wear resistance. For holes deeper than 3x diameter, through-coolant capabilities become almost mandatory.

The center insert in a drilling application often experiences different cutting conditions than the outer insert. When possible, select insert geometries specific to their position in the tool.

Optimizing Insert Size and Edge Preparation

When selecting carbide inserts, size and edge preparation significantly impact your machining results. The right choices here can mean the difference between mediocre cuts and optimal performance with longer tool life.

Size Selection for Stability and Material Removal Efficiency

Choosing the correct insert size is crucial for machining stability. Generally, we recommend selecting the largest insert size that’s practical for your specific application. Larger inserts (above IC 25mm) provide better stability during heavy machining operations.

Why does size matter so much? Larger inserts offer:

- Increased heat dissipation (heat spreads across more material)

- Better vibration resistance during cutting

- Higher material removal rates without compromising tool life

For smaller workpieces or tight spaces, you’ll need to balance size with accessibility. Remember that undersized inserts may flex under cutting pressure, causing chatter and poor surface finish.

When machining softer materials, smaller inserts can work well. But for tough materials like hardened steels or super alloys, the stability of larger inserts becomes essential.

Edge Preparation Options (Honed, Chamfered, Polished)

Edge preparation significantly impacts how your insert performs. We have three main options to consider:

Honed Edges: A slight radius (typically 0.001″-0.003″) that strengthens the cutting edge.

- Best for: General-purpose machining and semi-finishing operations

- Provides: Good balance between sharpness and edge strength

Chamfered Edges: A small flat area or angle on the cutting edge.

- Best for: Heavy roughing and interrupted cuts

- Provides: Maximum edge protection against chipping

Polished Edges: Smoothed surfaces that reduce friction and heat.

- Best for: Finishing operations and machining sticky materials

- Provides: Better surface finish and reduced built-up edge formation

Your material type should guide your choice. For example, tough materials benefit from chamfered edges, while aluminum works well with polished edges.

Impact on Tool Life and Cutting Performance

The right size and edge preparation choices directly affect your bottom line through tool life and performance. We’ve seen proper selection increase tool life by 25-50% in many applications.

Key performance impacts include:

- Surface finish quality – Polished edges typically produce better finishes

- Cutting forces – Larger inserts with proper edge prep reduce cutting forces

- Heat generation – Optimized edges reduce friction and heat

- Chip control – Edge preparation affects chip formation and evacuation

For high-volume production, even small improvements matter. A slightly more expensive insert with the right edge preparation might last twice as long as a cheaper alternative.

Testing different combinations on your specific application is the best approach. Start with manufacturer recommendations, then adjust based on your results.

Troubleshooting and Problem-Solving

Even the best carbide inserts eventually face challenges in machining operations. Knowing how to identify problems and implement solutions can save you time, money, and frustration on the shop floor.

Common Issues: Chipping, Wear, Built-Up Edges

When machining goes wrong, your inserts will show distinctive patterns of damage. Chipping often occurs when you’re using too high a feed rate or when the insert grade is too brittle for your application. Look for small fragments breaking off the cutting edge.

Normal flank wear appears as a uniform band along the cutting edge. While some wear is expected, excessive wear happens when cutting speeds are too high or you’re using the wrong grade for your material.

Built-up edges form when material from the workpiece welds itself to the cutting edge. This typically happens when:

- Cutting speeds are too low

- Feed rates are inadequate

- You’re machining sticky materials like aluminum without proper lubrication

We often see crater wear on the top face of inserts when machining hard materials at high temperatures. This can quickly lead to insert failure if not addressed.

Diagnosis and Solutions

How can you fix these common problems? First, examine your worn inserts carefully. The wear pattern tells a story about what’s happening during the cut.

For chipping problems, try:

- Reducing feed rates by 10-15%

- Switching to a tougher carbide grade

- Checking for machine vibration

- Ensuring proper tool support

To address excessive wear:

- Reduce cutting speed

- Select a harder carbide grade

- Improve cooling methods

- Verify your insert is properly seated

Built-up edge issues can be solved by:

- Increasing cutting speed

- Using proper coolant

- Selecting inserts with positive rake angles

- Applying coatings that reduce friction

Remember that proper diagnosis saves money. Taking phone photos of worn inserts and comparing them to wear charts (like Tungaloy’s) can help identify the exact issue.

When to Replace vs. Potential for Resharpening

Knowing when to replace your carbide inserts is crucial for maintaining productivity and part quality. Replace immediately when you notice:

- Chipping that extends past the wear land

- Crater wear approaching the cutting edge

- Complete edge breakdown

- Unexpected surface finish issues on your parts

Most indexable carbide inserts aren’t designed for resharpening, but some solid carbide tools can be reconditioned. We recommend considering resharpening when:

- You use expensive special-profile tools

- The tool body remains in good condition

- You have access to professional resharpening services

The economics matter too. Calculate the cost of downtime against the price of new inserts. Modern inserts often have multiple cutting edges – use all available edges before replacement.

For high-volume production, establish regular replacement intervals based on part counts rather than waiting for visible wear to avoid inconsistent part quality.

Best Practices for Maximizing Carbide Insert Lifespan

Extending the life of your carbide inserts saves money and improves machining consistency. With proper techniques and care, you can significantly increase how long these valuable tooling components last in your operations.

Proper Usage Techniques

When using carbide inserts, always start with the correct cutting parameters. We recommend following manufacturer guidelines for speed, feed, and depth of cut based on the workpiece material. Going too fast generates excessive heat that rapidly degrades the insert coating.

Avoid interrupted cuts when possible, as these create impact forces that can chip the insert. If you must machine interrupted surfaces, reduce your cutting speed by 20-30%.

For optimal tool life, use cutting fluid consistently. This helps carry away heat and chips while lubricating the cutting zone. Remember that dry machining accelerates wear, even with modern coated inserts.

Make gradual depth adjustments rather than plunging directly to full depth. This progressive approach reduces stress on the cutting edge and prevents premature failure.

Maintenance Recommendations

Regular inspection is crucial for maximizing insert life. We suggest checking edges after each operation for signs of wear, chipping, or built-up edge. Using a 10x magnifier helps spot early damage before it affects part quality.

Clean inserts thoroughly between uses. Compressed air works well, but be careful not to blow chips into your skin or eyes. For stubborn materials:

- Use a soft brush for aluminum build-up

- Apply appropriate solvents for stuck-on material

- Never use metal tools to scrape inserts clean

Rotate inserts when one edge shows wear to utilize all cutting edges before replacement. Most square inserts have 4-8 usable edges, so track usage systematically with a simple log or marking system.

Storage and Handling Guidelines

Store carbide inserts in their original packaging or in dedicated containers with compartments. This prevents edges from contacting each other, which can cause microscopic damage.

Temperature and humidity control matters more than you might think. We recommend keeping inserts in a dry environment below 70% humidity to prevent corrosion of the substrate or binder materials.

When handling inserts:

- Use tweezers or gloved hands to prevent skin oils from contaminating surfaces

- Avoid dropping inserts as they’re brittle and can crack from impact

- Place inserts gently into tool holders without forcing them

Label storage containers clearly with insert specifications. This simple step prevents mix-ups that lead to using the wrong insert type for a job—a common cause of premature failure and poor results.

Case Studies: Success Stories and Real-World Applications

The right carbide inserts can transform machining operations as demonstrated by numerous companies across different industries. These real-world examples showcase how proper insert selection leads to measurable improvements in efficiency, cost savings, and overall production quality.

Industry Examples Demonstrating Proper Insert Selection

Aerospace Manufacturing An aerospace parts manufacturer struggled with inconsistent tool life when machining titanium components. After switching to PVD-coated carbide inserts with a specialized geometry, they saw 5x longer tool life and reduced machine downtime by 40%.

Automotive Production A leading auto parts supplier needed to increase throughput for cast iron engine blocks. By selecting carbide inserts with chip-breaking geometries specifically designed for interrupted cutting, they achieved:

- 30% faster cutting speeds

- Improved surface finish quality

- 25% reduction in insert changes

Medical Device Manufacturing When machining surgical implants from stainless steel, a medical device company faced challenges with tight tolerances. Their switch to precision-ground carbide inserts with multi-layer coatings resulted in consistently meeting ±0.001″ tolerances while reducing inspection rejections.

Before/After Performance Improvements

Case 1: CNC Turning Operation Before: A job shop used general-purpose inserts for all turning operations, experiencing frequent edge chipping and unpredictable tool life.

After: By matching insert grades to specific workpiece materials, they achieved:

- Tool life improvement: 127%

- Cycle time reduction: 18%

- Scrap rate decrease: from 3.2% to 0.8%

Case 2: Heavy Milling Application Before: Excessive heat generation and poor chip evacuation caused premature insert failure.

After: Implementing carbide inserts with specialized coatings and geometry:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Parts per insert | 35 | 120 | 243% |

| Surface finish | Ra 3.2 | Ra 1.6 | 50% better |

| Machine downtime | 2.5 hrs/day | 0.5 hrs/day | 80% reduction |

ROI Analysis

We’ve found that investing in application-specific carbide inserts delivers significant financial returns. A metal fabrication company switching from standard inserts to premium carbide varieties showed these results:

Initial investment increase: $12,500 annually for higher-quality inserts

Annual savings:

- $28,000 in reduced tooling changes

- $45,000 in increased production output

- $18,500 in decreased scrap and rework

Their total ROI was 7.3:1, meaning every dollar spent on better inserts returned $7.30 in operational improvements.

For small machine shops, the payback period typically ranges from 2-6 months. One job shop processing stainless steel components calculated a monthly savings of $4,200 after spending an additional $1,400 on specialized carbide inserts, achieving complete cost recovery in just 10 days.

Future Trends in Carbide Insert Technology

The carbide insert industry is changing fast with exciting new developments on the horizon. Manufacturers are creating smarter, more efficient, and environmentally friendly options that will transform how we approach machining tasks.

Emerging Materials and Designs

Have you heard about the nano-composite carbide materials being developed? These new materials combine traditional tungsten carbide with nano-scale particles to create inserts with superior hardness and wear resistance. We’re seeing impressive results in early testing – up to 30% longer tool life in high-speed applications!

Smart coatings are another game-changer. Modern multi-layer coatings can now be customized for specific machining tasks. For example:

- AlTiN coatings for high-temperature applications

- nACo® coatings for improved wear resistance

- Diamond-like carbon (DLC) for non-ferrous materials

Sensor integration is perhaps the most exciting trend. Tiny sensors embedded in inserts can now monitor temperature, wear, and cutting forces in real-time. This helps prevent tool failure and optimize cutting parameters automatically.

Sustainability Considerations

Environmental impact is becoming a major focus in carbide insert development. Did you know that tungsten carbide recycling programs can now recover up to 95% of materials from used inserts? This significantly reduces the need for new raw materials.

Manufacturers are exploring alternative binders to traditional cobalt, which has supply chain and environmental concerns. Iron-nickel alloys and other sustainable binders show promise in reducing the environmental footprint without sacrificing performance.

Production methods are also becoming greener. New sintering techniques reduce energy consumption by up to 40% compared to traditional methods. We’re also seeing water-based coolant systems replacing oil-based options.

Have you considered the full lifecycle impact of your tooling choices? The industry is moving toward comprehensive sustainability metrics that account for raw material extraction through recycling.

What to Expect in Next-Generation Inserts

3D printing technology is revolutionizing insert manufacturing. Custom-designed inserts with internal cooling channels and complex geometries impossible with traditional methods are now becoming available. This means better heat management and longer tool life.

Modular insert systems will become more common, allowing quick changes between operations without needing completely different tooling setups. This reduces downtime and inventory costs significantly.

AI-driven tool selection is perhaps the most transformative advancement coming. Systems will analyze your specific machining needs and automatically recommend the optimal insert grade, geometry, and cutting parameters. Early adopters report productivity increases of 15-25%!

What about self-sharpening inserts? Cutting-edge research is developing inserts with layered materials that gradually reveal new cutting edges as they wear, extending useful life dramatically.