Are you confused about cemented carbide and tungsten carbide? We often hear these terms used interchangeably in industrial settings, which can be quite puzzling. While tungsten carbide refers to the specific material combining tungsten and carbon, cemented carbide is actually a broader category that includes tungsten carbide bound with a metal binder (usually cobalt).

When people in industry talk about “carbide” or “tungsten carbide,” they’re typically referring to cemented carbide composites. These materials are incredibly valuable in manufacturing due to their exceptional hardness, wear resistance, and toughness. You’ll find them in cutting tools, mining equipment, and even jewelry!

We’ve noticed many of our customers wonder about the difference between these terms. The simple way to remember it is that tungsten carbide is a specific type of cemented carbide. All cemented carbides with hardness exceeding HRC65 fall into this category, making tungsten carbide a subset of the broader cemented carbide family.

Fundamentals: What Are Cemented Carbide And Tungsten Carbide?

Understanding these materials can be confusing due to overlapping terminology in the industry. Let’s clear up the confusion about these incredibly hard materials that play a vital role in manufacturing and tooling applications.

Clear Definitions Of Both Materials

Cemented carbide is a composite material made of fine particles of carbide cemented together by a metal binder. The most common type contains tungsten carbide (WC) particles held together by cobalt. This creates a material with excellent hardness and wear resistance.

Think of cemented carbide like a chocolate chip cookie. The carbide particles are the chocolate chips, and the binder metal is the cookie dough holding everything together.

The most important feature of cemented carbide is its combination of hardness and toughness. With a Vickers hardness of around 10,000, it’s second only to diamond in hardness while maintaining enough toughness for industrial applications.

Their Relationship And Common Misconceptions

The biggest misconception is thinking these are completely different materials. In reality, tungsten carbide is a specific compound (WC), while cemented carbide is the finished composite material that often contains tungsten carbide.

When someone mentions “tungsten carbide tools,” they’re usually referring to cemented carbide tools where tungsten carbide is the main carbide component. Pure tungsten carbide without a binder would be too brittle for most applications.

Another common mix-up involves tungsten steel. According to our search results, tungsten steel is actually classified as a type of cemented carbide, sometimes called tungsten-titanium alloy.

All materials with hardness exceeding HRC65 can be called cemented carbide, making it a broader category that includes tungsten steel.

Key Terminology For Industry Professionals

When working with these materials, you’ll need to know these key terms:

- WC: Chemical symbol for tungsten carbide compound

- Binder: Metal (usually cobalt) that holds carbide particles together

- Grain size: Affects hardness and wear resistance (finer = harder)

- Cobalt content: Higher percentages increase toughness but reduce hardness

Hardness measurements are typically done using the Vickers scale for these materials. For comparison:

| Material | Approximate Vickers Hardness |

|---|---|

| Cemented Carbide | 1000-2000 |

| Pure Tungsten Carbide | 2200+ |

| Diamond | 10000 |

We often see “solid carbide” used interchangeably with cemented carbide in product descriptions, which can add to the confusion for buyers new to these materials.

Composition And Manufacturing Processes

Understanding what goes into cemented carbide and tungsten carbide helps explain their unique properties. The materials start with similar ingredients but differ in processing and final composition.

Detailed Breakdown Of Material Components

Cemented carbide is a composite material made of hard carbide particles bonded together with a softer metal. The main components include:

- Tungsten carbide (WC): 80-97% of the composition

- Binder metals: Usually cobalt (Co) at 3-20%, though nickel (Ni) may be used for corrosion resistance

- Additional carbides: Sometimes titanium, tantalum, or niobium carbides are added

The grain size of tungsten carbide particles significantly impacts the final properties. We classify carbides as:

- Fine grain (less than 1 μm): Higher hardness, better wear resistance

- Medium grain (1-3 μm): Balanced properties

- Coarse grain (greater than 3 μm): Better impact resistance, toughness

Pure tungsten carbide, in contrast, contains only tungsten and carbon atoms in a crystalline structure without a binder metal.

Step-by-Step Manufacturing Methods

How are these materials made? Let’s look at the typical process:

- Powder preparation: Raw tungsten and carbon powders are mixed with binder metals (cobalt/nickel)

- Milling: The mixture is wet-milled to reduce particle size and ensure even distribution

- Drying and granulation: The slurry is dried and formed into granules suitable for pressing

- Pressing: The powder is compressed into the desired shape using dies

- Sintering: This crucial step happens at 1300-1500°C under vacuum or protective atmosphere

During sintering, the binder metal melts and flows between carbide particles, creating a solid mass. This is why cemented carbide is sometimes called a “cemented” material – the binder literally cements everything together.

How Composition Affects Performance

The ratio of carbide to binder dramatically affects performance characteristics. We see clear trends:

Higher tungsten content increases hardness and wear resistance but decreases toughness. More binder metal does the opposite – improving toughness while reducing hardness.

Grain size matters too! Fine-grained carbides resist wear better but are more brittle. Coarse-grained versions can absorb more impact.

Different carbide grades are engineered for specific applications. For cutting tools, we might use grades with 6% cobalt and fine grains. For mining tools that face harsh impacts, grades with 10-15% cobalt and medium-to-coarse grains work better.

The type of binder also matters – while cobalt provides excellent wetting and adhesion to tungsten carbide, nickel offers better corrosion resistance.

Visual Comparison Table Of Composition Differences

| Feature | Cemented Carbide | Tungsten Carbide (Pure) |

|---|---|---|

| Main components | WC (80-97%) + binder metal (3-20%) | WC only (tungsten + carbon) |

| Binder metals | Cobalt, nickel, or iron | None |

| Typical grain size | 0.5-10 μm (controllable) | N/A (single phase material) |

| Additional compounds | May contain TiC, TaC, NbC | None |

| Manufacturing | Powder metallurgy + sintering | Direct carburization of tungsten |

| Hardness range | 89-93 HRA (varies with composition) | ~93 HRA (fixed) |

| Flexibility | Highly customizable properties | Limited property adjustment |

We can see that cemented carbide offers much more flexibility in composition, allowing manufacturers to tailor properties for specific applications. The refractory metal compounds provide heat resistance while the bonding metal gives the material its toughness.

Performance Metrics: A Comprehensive Comparison

When comparing cemented carbide and tungsten carbide, understanding their performance metrics helps you select the right material for your application. The differences in hardness, strength, and wear characteristics directly impact tool life and productivity in industrial settings.

Hardness, Toughness, And Wear Resistance Data

Cemented carbide typically achieves hardness values exceeding HRC65 (often reaching above 90HRA), making it significantly harder than conventional tool steels. This exceptional hardness comes from the tungsten carbide particles embedded in the cobalt binder.

Tungsten carbide, as a primary component in cemented carbide, contributes to this extreme hardness. The wear resistance of these materials is remarkable – they can last 5-100 times longer than high-speed steel in abrasive applications.

Fracture toughness varies based on composition. Materials with higher cobalt content (8-12%) offer better impact resistance but slightly reduced hardness. For comparison:

| Material Type | Hardness (HRA) | Fracture Toughness (MPa·m^(1/2)) |

|---|---|---|

| Fine-grain WC-Co (6%) | 92-93 | 9-11 |

| Medium-grain WC-Co (10%) | 89-91 | 12-15 |

| High-speed steel | 80-86 | 20-25 |

The size ratio between carbide grain size and abrasive particles significantly impacts wear performance in different applications.

Compressive Strength And Density Comparisons

Cemented carbides demonstrate exceptional compressive strength, typically in the range of 3,000-7,000 MPa, which is about 2-3 times higher than high-speed steel. This makes them ideal for high-pressure cutting and forming operations.

Density is another key metric. Cemented carbides have a density of approximately 13-15 g/cm³, significantly higher than high-speed steel’s 8-9 g/cm³. This higher density contributes to their stability during machining operations.

The transverse rupture strength (TRS) measures a material’s ability to resist bending forces:

- Fine-grain carbides (6% Co): 1,800-2,400 MPa

- Medium-grain carbides (10% Co): 2,500-3,000 MPa

- Coarse-grain carbides (15% Co): 2,800-3,200 MPa

We’ve found that higher cobalt content improves TRS but slightly decreases hardness and wear resistance. This trade-off is crucial when selecting materials for specific applications.

Industry-standard Testing Results

Standard industry tests provide reliable metrics for comparing carbide performance. The Rockwell hardness test (HRA scale) is commonly used, with cemented carbides typically scoring above 90, compared to high-speed steel’s 80-86.

Abrasion resistance testing shows cemented carbides outlast conventional tool steels by significant margins. In standardized pin-on-disk tests, cemented carbides show 5-10 times less volume loss than high-speed steel.

Impact strength testing reveals interesting results. When subjected to repeated impact:

- Higher cobalt grades (12-15%) show better impact resistance

- Fine-grain structures provide better edge retention

- Cubic carbide additions (TiC, TaC) improve thermal stability

Nitrided cemented carbides have shown impressive results in recent testing. The cubic carbide enriched outer layer acts similarly to a coating, significantly enhancing wear performance in high-temperature applications.

Application-specific Performance Characteristics

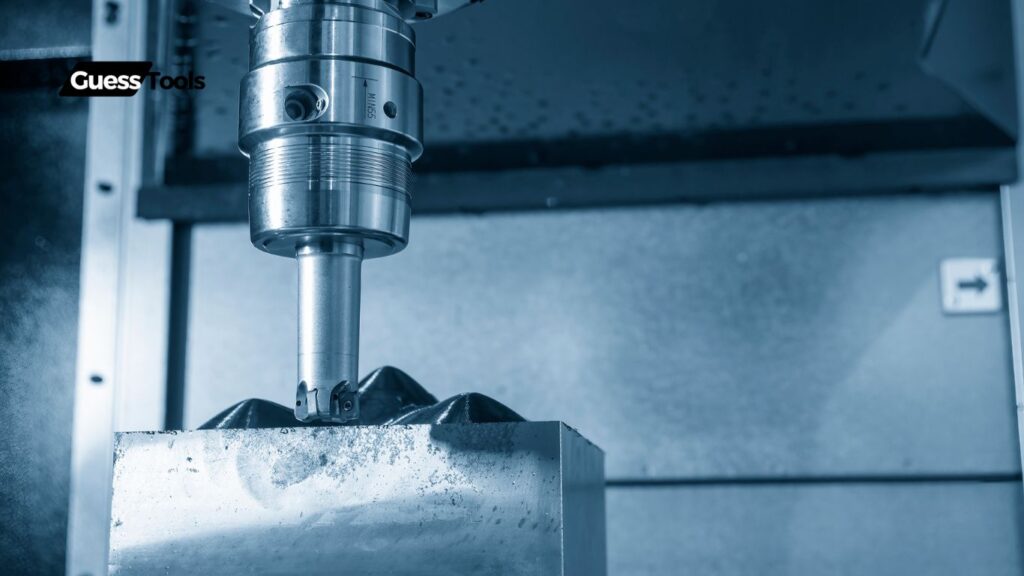

In metal cutting applications, we see cemented carbide tools operating at speeds 2-4 times higher than high-speed steel. This translates directly to increased productivity and reduced machining time.

For mining and earth-moving equipment, impact resistance becomes crucial. Grades with 10-15% cobalt content provide the optimal balance between wear resistance and toughness in these demanding environments.

The advantages of cemented carbide in high-temperature applications are substantial:

- Maintains hardness at temperatures up to 800°C

- Resists thermal deformation

- Exhibits superior chemical stability when cutting reactive materials

In precision tooling, fine-grain cemented carbides excel due to their ability to maintain sharp cutting edges while withstanding high cutting forces. Their dimensional stability during heat treatments makes them perfect for dies and molds requiring tight tolerances.

Hot hardness is another area where cemented carbides outperform steel. While high-speed steel softens significantly above 500°C, cemented carbides retain most of their hardness up to 800-1000°C, allowing for higher cutting speeds.

Industrial Applications: Cemented Carbide vs Tungsten Carbide

Choosing between cemented carbide and tungsten carbide depends on specific industry needs. The right material selection can dramatically improve performance, cost-efficiency, and tool life in various applications.

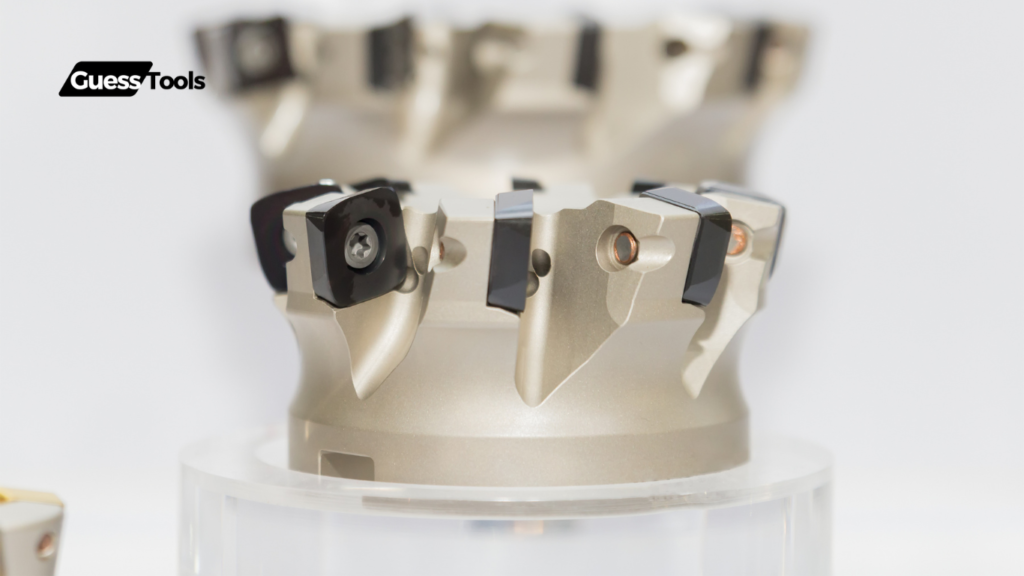

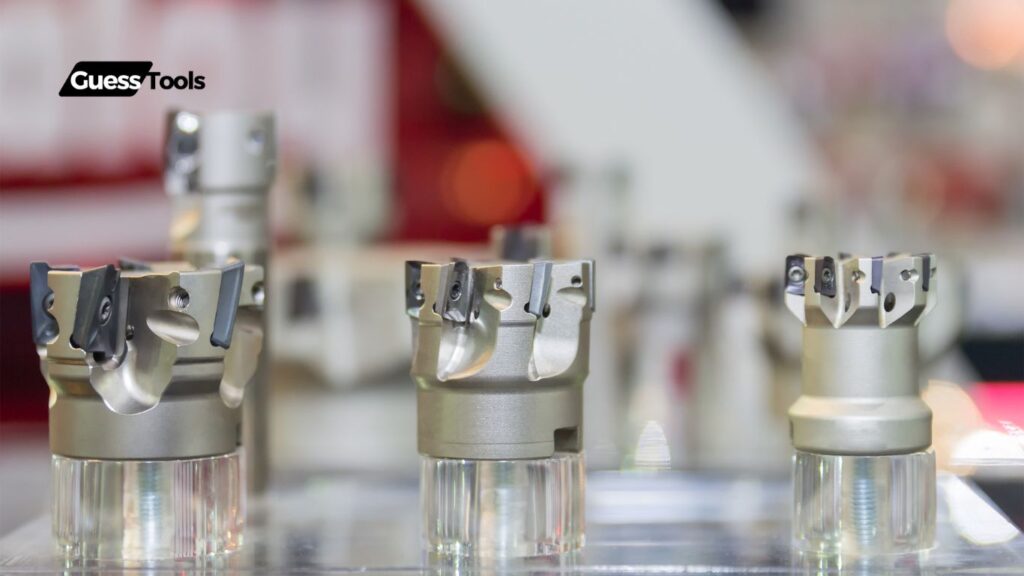

Machining And Cutting Tools

In machining operations, cemented carbide tools offer impressive performance advantages. These tools typically contain tungsten carbide particles in a cobalt binder, creating an ideal balance of hardness and toughness.

Did you know that cemented carbide cutting tools can operate at speeds 3-5 times faster than high-speed steel? This boost in productivity makes them the go-to choice for high-volume manufacturing processes.

When working with harder materials like stainless steel or titanium, we’ve found that carbide tools with specialized coatings perform exceptionally well. These coatings reduce friction and heat generation during cutting.

Key applications include:

- Turning operations

- Milling cutters

- Drill bits

- Thread cutting tools

Tungsten carbide rods are commonly used to manufacture these tools, providing the raw material for custom tooling solutions.

Mining And Drilling Applications

The extreme conditions of mining and drilling demand materials that can withstand intense abrasion and impact. Here, the distinction between grades of carbide becomes crucial.

Cemented carbide with higher cobalt content (8-12%) offers better impact resistance for rock drilling. In contrast, grades with less cobalt (4-6%) provide superior wear resistance for continuous cutting applications.

We’ve observed that tungsten carbide drill bits last up to 100 times longer than steel bits in hard rock conditions. This dramatic improvement in tool life translates to fewer replacements and less downtime.

Popular components include:

- Drill bits for oil and gas exploration

- Mining picks

- Tungsten carbide nozzles for sand blasting

- Tunnel boring machine cutters

These applications benefit from carbide’s unique combination of hardness (90-92 HRA) and compressive strength (up to 7,000 MPa).

Wear Parts And Specialized Components

In industries facing extreme wear challenges, tungsten carbide components provide exceptional service life. The material’s resistance to abrasion, erosion, and chemical attack makes it ideal for demanding environments.

Tungsten carbide nozzles are particularly valuable in spray applications. We’ve found they maintain their dimensions up to 20-30 times longer than steel alternatives when handling abrasive slurries or powders.

Common wear applications include:

- Flow control valves

- Extrusion dies

- Seal rings

- Wire drawing dies

The material selection process must consider the specific wear mechanism. For sliding wear, finer-grained carbides with higher hardness excel. For impact wear, coarser grades with higher cobalt content perform better.

Case Studies Of Successful Implementations

A major automotive manufacturer switched to cemented carbide cutting tools for cylinder head machining. The result? Production rates increased by 35% while tool change frequency decreased by 70%.

In oil drilling, a company implementing tungsten carbide nozzles in their drilling mud system reduced nozzle replacements from weekly to quarterly intervals. This change saved approximately $120,000 annually in replacement costs and downtime.

A mining operation in Australia replaced standard steel components with custom tungsten carbide wear parts in their ore processing equipment. The new parts lasted 8 times longer, reducing maintenance downtime by 45%.

These real-world examples show how strategic material selection can transform operational efficiency. The initial higher cost of carbide components is typically offset by their dramatically longer service life and improved performance.

Economic Considerations For Manufacturers

When choosing between cemented carbide and tungsten carbide, manufacturers need to evaluate several economic factors that affect their bottom line. The right decision can lead to significant cost savings and improved productivity in the long run.

Cost Analysis And ROI Calculations

The initial investment in cemented carbide tools is typically higher than traditional alternatives. However, this cost is often offset by longer tool life and improved efficiency. Let’s break down the numbers:

- Initial cost: Cemented carbide may cost 20-40% more upfront

- Production speed: Can increase output by 25-50% in many applications

- Replacement frequency: Longer intervals between tool changes

We’ve found that most manufacturers see a return on investment within 3-6 months when switching to cemented carbide. This ROI calculation should include not just the tool cost but also reduced downtime for tool changes and increased production capacity.

For example, a manufacturing plant that invested $12,000 in cemented carbide cutting tools saw a 32% increase in production speed and reduced tool replacement by 40%, resulting in annual savings of approximately $38,000.

Supply Chain Considerations

The tungsten carbide market is expected to grow from $5.69 billion in 2023 to $14.54 billion by 2031, which may affect both availability and pricing.

Key supply chain factors to consider include:

- Sourcing reliability: China produces about 80% of the world’s tungsten

- Material availability: Potential fluctuations due to mining regulations

- Lead times: Custom cemented carbide tools may require longer wait times

We recommend developing relationships with multiple suppliers to mitigate risk. Some manufacturers have implemented just-in-time inventory systems specifically for their carbide tooling to balance availability with carrying costs.

Supply chain disruptions can significantly impact production, so it’s worth considering how critical these tools are to your operation.

Maintenance And Tool Life Factors

Cemented carbide tools typically offer 5-10 times longer tool life compared to conventional alternatives in most applications. This extended lifespan directly impacts your maintenance budget and production schedule.

Maintenance considerations:

- Proper training for operators on correct use of carbide tools

- Regular inspection schedules to identify wear before failure

- Appropriate cleaning and storage protocols

Tool life can be further extended through proper cooling techniques during operation. One manufacturer reported a 35% increase in carbide tool life simply by optimizing their coolant system at a cost of just $2,000.

Remember that tool failure often leads to workpiece damage, which adds hidden costs beyond just replacing the tool itself.

Long-term Value Assessment

Beyond immediate cost considerations, we need to evaluate the total value proposition of cemented carbide tooling.

Long-term benefits include:

- Improved surface finish quality (reducing secondary operations)

- More precise tolerances (fewer rejected parts)

- Ability to machine harder materials (expanding capabilities)

- Reduced energy consumption (up to 15% in some cases)

When factoring in these additional benefits, the value equation shifts significantly. A comprehensive assessment should include quality improvements, waste reduction, and expanded production capabilities.

For a mid-sized manufacturing operation, these benefits typically translate to an additional 10-15% cost advantage beyond the direct tool life and productivity gains, making cemented carbide a clear economic winner for most high-volume or precision applications.

Guess Tools Expert Guide To Material Selection

Selecting the right material for your cutting tools can make a huge difference in performance and cost. We’ve put together this guide to help you navigate the complex world of cemented carbide and tungsten carbide options based on our decades of experience in the field.

Application-specific Recommendations

Are you working with hard metals or soft materials? This question matters a lot when choosing between carbide types. For high-speed machining of steel, we recommend fine-grained cemented carbide with 6-10% cobalt content for the best balance of wear resistance and toughness.

When cutting cast iron or non-ferrous metals, a straight tungsten carbide grade with lower cobalt content (4-6%) works extremely well. The higher hardness prevents premature wear.

For wood processing tools, medium-grain carbide with 10-15% cobalt provides the shock resistance needed to handle knots and varying densities.

Consider these factors:

- Workpiece material hardness

- Cutting speed requirements

- Wet vs. dry machining conditions

- Required surface finish quality

Remember that harder isn’t always better! Sometimes a slightly softer grade with better toughness will outlast a harder grade in interrupted cutting applications.

Industry Best Practices

We’ve found that most machining failures come from improper material selection. Follow these industry-proven guidelines for best results:

- Match the carbide grain size to your application:

- Nanograin (<0.2μm): Precision tools, excellent finish

- Fine grain (0.5-0.8μm): General purpose

- Medium grain (1.0-1.5μm): Heavier cuts, more impact resistance

- Coarse grain (2.0-6.0μm): Maximum toughness for roughing

- Consider the full cutting environment, not just the material being cut. Coolant availability, machine rigidity, and toolholder quality all affect what carbide grade will perform best.

Always run test cuts when possible. What works in theory doesn’t always translate to real-world success. We’ve seen cases where a slightly “wrong” grade according to charts outperformed the “correct” one because of unique machine characteristics.

Troubleshooting Common Issues

Is your tungsten carbide tool wearing too quickly? You might need a grade with higher hardness or different coating. Excessive edge chipping? Consider a grade with more cobalt binder for improved toughness.

Common problems and solutions:

| Problem | Potential Solution |

|---|---|

| Rapid wear | Increase WC content, reduce grain size |

| Edge chipping | Increase cobalt percentage |

| Built-up edge | Try PVD coating or polished edge |

| Tool breakage | Check for proper support, increase toughness |

Remember that temperature plays a huge role in carbide performance. If your tools are running hot, even the best grade selection can fail prematurely. Ensure proper cooling and don’t exceed recommended cutting speeds.

We’ve found that about 60% of carbide tool failures stem from improper application rather than material quality issues. Check your cutting parameters before blaming the tool!

Custom Solution Options

Can’t find the perfect carbide grade for your unique application? You’re not alone. We work with manufacturers to develop custom carbide formulations for specific challenges.

Several options exist for customization:

- Multi-layer carbide structures with tough core and hard outer layer

- Gradient carbide with varying cobalt content throughout the tool

- Specialized binders beyond traditional cobalt, including nickel, iron, or chromium variants

Custom solutions typically require minimum order quantities and development time. For critical applications with high volume, the investment pays off through extended tool life and improved productivity.

Have you considered alternative coatings? While the base carbide is crucial, specialized PVD or CVD coatings can dramatically change performance characteristics without requiring completely new carbide formulations.

Future Innovations In Carbide Technology

The carbide industry is on the verge of exciting breakthroughs that will transform how these materials are produced and used. Advances in manufacturing processes, coatings, and sustainability are reshaping what’s possible with both cemented and tungsten carbide technologies.

Emerging Trends And Research Directions

Research in carbide technology is moving faster than ever. We’re seeing major advances in nano-structured carbides that provide better hardness-to-toughness ratios than traditional materials. Have you considered how these might affect your industry?

Scientists are developing carbide composites with ceramic reinforcements that can withstand even higher temperatures—up to 1200°C in some cases! This opens new possibilities for aerospace and high-temperature manufacturing applications.

3D printing of carbide parts is another game-changer. Companies can now produce complex geometries that were impossible with traditional sintering methods. This means custom carbide tools with internal cooling channels and optimized cutting edges.

Some interesting developments include:

- Gradient carbides with varying composition throughout the part

- Self-healing carbide materials that can repair micro-cracks

- Ultra-fine grain structures (<0.2 μm) for superior wear resistance

New Coating Technologies

Coatings are revolutionizing carbide performance. The latest PVD (Physical Vapor Deposition) coatings can extend tool life by 300% compared to uncoated carbides. Isn’t that impressive?

Multi-layer coatings combine the benefits of different materials. For example, a TiAlN base layer provides heat resistance while a diamond-like carbon top layer offers lubricity and wear resistance.

Researchers at leading universities have developed “smart coatings” that respond to changing conditions. These coatings can release lubricants when friction increases or harden when exposed to higher pressures.

Some exciting new coating technologies include:

- Hydrogen-free diamond-like carbon (DLC) coatings

- Nanocomposite coatings with self-lubricating properties

- AlCrSiN coatings for high-temperature machining

- Oxide-based coatings for corrosion resistance in chemical applications

Sustainability And Recycling Developments

The carbide industry is getting much greener. New recycling methods can recover up to 95% of tungsten from used carbide tools, reducing the need for mining.

Water-based processing is replacing harmful solvents in carbide production. This cuts VOC emissions by 80% while maintaining product quality. We’ve seen companies adopt closed-loop water systems that eliminate wastewater discharge completely.

Alternative binders are replacing traditional cobalt, which has supply chain and health concerns. Iron-nickel alloys provide similar performance with reduced environmental impact.

Key sustainability initiatives include:

- Powder reclamation systems that recover material during grinding

- Energy-efficient sintering using microwave technology

- Bio-based binders derived from renewable resources

- Zero-waste manufacturing facilities

What To Expect In The Next 5 Years

In the coming years, we’ll see carbide tools that last twice as long as current options. Machine learning algorithms will optimize carbide compositions for specific applications, creating truly customized solutions.

Digital twins of carbide manufacturing processes will enable real-time quality control and predictive maintenance. This could reduce production costs by 20-30% according to industry forecasts.

The market for specialized carbides in emerging industries like hydrogen fuel cells and quantum computing will grow by an estimated 12% annually. These applications demand unique properties that only advanced carbides can provide.

How will this affect you? Expect more affordable and specialized carbide options as production efficiency improves. We’ll also see greater integration between carbide suppliers and end-users through digital platforms that optimize tool selection and usage.

Conclusion & Resources

Understanding the differences between cemented carbide and tungsten carbide is essential for making the right material choices in your industrial applications. Let’s explore the key differences, provide some helpful resources, and explain how our team can assist you further.

Summary Of Key Differences And Selection Criteria

When choosing between cemented carbide and tungsten carbide, remember that tungsten carbide is actually a component of cemented carbide. Cemented carbide is a composite material that contains tungsten carbide particles bound together with a metal binder (typically cobalt). Tungsten, on the other hand, is just the individual metal element.

Key selection factors to consider:

- Hardness vs. Toughness: Cemented carbide offers an excellent balance of hardness and toughness compared to tungsten steel

- Application requirements: Consider wear resistance, temperature conditions, and chemical exposure

- Cost factors: Higher tungsten content typically means higher cost but better performance in certain applications

- Lifespan expectations: Cemented carbide generally offers superior resistance to plastic deformation due to its higher yield strength

When selecting between these materials, we recommend evaluating your specific operating conditions, budget constraints, and performance requirements.

Additional Resources And Tools

We’ve compiled some valuable resources to help deepen your understanding of carbide materials:

Technical Guides:

- The Cemented Carbide Designer’s Guide – Comprehensive material properties and selection criteria

- Carbide Material Safety Data Sheets – Important handling and safety information

Online Tools:

- Our interactive material selector tool at guess-tools.com/material-selector

- Carbide wear calculator for estimating lifespan in various applications

Industry Publications:

- Modern Manufacturing magazine’s special issue on carbide applications

- The quarterly Carbide Technology Review with the latest research findings

These resources can help you make more informed decisions about which carbide material best suits your specific needs.

Call To Action For Consultation With Guess Tools Experts

Not sure which carbide material is right for your application? Our Guess Tools experts are here to help! We have over 15 years of experience working with carbide materials across numerous industries.

How we can assist you:

- Free 30-minute consultation to discuss your specific application needs

- Custom material analysis and recommendation report

- Sample testing to verify performance before large purchases

Contact us today at info@guesstools.com. We pride ourselves on finding the perfect material solution for challenging industrial applications.

Why struggle with material decisions alone? Let our team help you maximize performance while optimizing your budget!