End mills are essential tools in machining, and two popular types are ball nose and flat end mills. These cutting tools serve different purposes in the manufacturing process.

Ball nose end mills have rounded tips that excel at creating smooth contours and 3D shapes, while flat end mills have flat cutting heads ideal for milling flat surfaces and slots. The choice between these two types depends on the specific machining task at hand.

Ball nose end mills are often used for finishing work and complex 3D contours. They produce a rounded pass and can achieve a high-quality surface finish. Flat end mills, on the other hand, are better suited for creating flat surfaces, sharp corners, and precise slots. Understanding the differences between these two types of end mills helps machinists select the right tool for each job.

Essential Differences Between Ball Nose and Flat End Mills

Ball nose and flat end mills have key differences in shape and function. These differences affect how they perform in various machining tasks.

Geometric Distinctions

Ball nose end mills have a rounded tip that forms a half-sphere. This curved profile allows them to create smooth contours and 3D shapes. Flat end mills have a straight edge at the tip. Their flat bottom is ideal for making precise vertical cuts and flat surfaces.

The rounded tip of ball nose mills can range from very small to large radii. Flat end mills come in various diameters but always maintain a 90-degree angle at the corners.

Implications for Machining Operations

Ball nose mills excel at 3D contouring and finishing curved surfaces. They’re great for relief artwork, molds, and dies. The rounded tip leaves small ridges called “scallops” between passes.

Flat end mills are better for:

- Cutting straight walls

- Making flat-bottomed pockets

- Slotting operations

- Face milling large flat areas

Flat mills remove material faster but may leave sharper corners. Ball nose mills provide smoother finishes on contoured parts.

Material Considerations

Both types work on metals, plastics, and wood. But their performance varies by material.

Ball nose mills:

- Handle softer materials well

- Good for aluminum and composites

- Struggle with very hard metals

Flat end mills:

- Effective on steel and titanium

- Can be used on most materials

- May chip when cutting hard metals

Tool life depends on material and cutting conditions. Carbide tools last longer than steel ones for both types. Proper speeds and feeds are crucial for any end mill to perform well and last.

Applications and Suitability: Ball Nose and Flat End Mill

Ball nose and flat end mills have distinct uses in machining. Their unique shapes make them suited for different tasks and materials. Let’s look at where each type shines.

Industrial Use Cases

Ball nose end mills excel in aerospace and automotive manufacturing. They’re great for making turbine blades and complex car parts. These tools can create smooth 3D shapes and fine details.

Flat end mills are workhorses in general manufacturing. They cut flat surfaces and straight edges quickly. Many factories use them to make parts for machines and consumer goods.

Both types find homes in the medical field. Ball nose mills craft precise implants. Flat mills cut the tools doctors use every day.

Optimizing for Materials and Shapes

For soft metals like aluminum, flat end mills are often the top pick. They remove material fast and leave a smooth finish. But when working with hard steels, ball nose mills can be more efficient. Their curved tip spreads out the cutting force.

Flat mills are best for:

- Square corners

- Straight slots

- Flat bottoms

Ball nose mills shine when making:

- Curved surfaces

- Rounded edges

- Detailed engravings

The shape you’re cutting matters too. For sharp angles, use a flat mill. For flowing lines, grab a ball nose. Smart tool choice makes your work faster and better.

Technical Specifications and Selection

End mill selection involves key factors like coatings, materials, geometry, and performance characteristics. These elements impact the tool’s capabilities and suitability for different machining tasks.

Coatings and Materials

End mills come in various materials and coatings. High-speed steel (HSS) tools offer good toughness at a lower cost. Solid carbide end mills provide higher hardness and heat resistance. Tungsten carbide tools excel in wear resistance and cutting speed.

Coatings enhance performance:

- TiN (Titanium Nitride): Improves wear resistance

- AlTiN: Boosts heat resistance

- ZrN: Reduces friction

The choice depends on the workpiece material and cutting conditions. Coated tools often last longer and can handle higher speeds.

Geometry and Design Features

End mill geometry affects cutting performance. Key features include:

- Number of flutes: 2-4 flutes for most applications

- Helix angle: Higher angles for better chip evacuation

- Cutting edges: Sharp for softer materials, stronger for harder materials

Center-cutting vs non-center cutting:

- Center-cutting: Can plunge straight down

- Non-center cutting: Better for side milling

Tapered end mills offer added strength near the shank. Different geometries suit various tasks, from roughing to finishing.

Precision and Performance Factors

Precision and performance hinge on several factors:

- Rigidity: Affects accuracy and surface finish

- Runout: Lower runout improves precision

- Cutting speed: Impacts tool life and surface quality

- Feed rate: Influences productivity and finish

Tool selection should balance these factors. Solid carbide tools often provide better rigidity and precision. Spiral flute designs can improve chip evacuation in deep cuts.

For high-precision work, consider:

- Fine-grain carbide

- Specialized coatings

- Optimized cutting edge preparation

Matching the tool to the job requirements ensures the best results in terms of accuracy, surface finish, and efficiency.

Milling Mechanics and Dynamics

The mechanics and dynamics of milling involve complex interactions between the tool, workpiece, and machine. These factors affect cutting performance and part quality.

Tool Movements and Techniques

Ball nose and flat end mills move differently when cutting. Flat end mills use straight plunging motions for slots and pockets. Ball nose mills employ arcing motions to create curved surfaces.

CNC machines control tool paths precisely. CAM software plans efficient routes. Proper plunge rates prevent tool breakage. Spindle speed impacts surface finish.

For ball nose mills, tilting the tool slightly can improve cutting. This reduces the effective cutting diameter at the tip. It also helps with chip evacuation.

Cutting Forces and Stability

Milling creates forces in multiple directions. Radial forces push sideways on the tool. Axial forces act along the tool’s length. Tangential forces occur at the cutting edge.

Tool deflection can cause inaccuracies. Larger tool diameters increase stiffness. Shorter stick-out length reduces vibration. Proper speeds and feeds maintain stability.

Balancing the tool assembly reduces chatter. This is especially important at high RPMs. Vibration dampening tool holders can help too.

Feedrate and Chip Evacuation

Feedrate affects material removal rate and tool life. Faster feeds increase productivity but may reduce quality. Slower feeds improve finish but take longer.

Proper chip evacuation prevents recutting. This is crucial for deep pockets and slots. Coolant helps flush chips away from the cutting zone.

Ball nose mills create smaller chips near the center. This can lead to buildup if not managed. Flat end mills produce more consistent chip sizes across the tool face.

Flute design impacts chip flow. More flutes can improve surface finish. Fewer flutes allow better chip evacuation in some cases.

Advanced Considerations for CNC Machining

CNC machining with ball nose and flat end mills requires careful planning and execution. Proper use of CAD/CAM systems, parameter adjustments, and tool management can boost efficiency and quality.

Programming with CAM and CAD Systems

CAD software helps create precise 3D models for CNC machining. It allows users to design complex shapes and set tool paths. CAM systems then convert these designs into machine-readable code.

For ball nose end mills, CAM software can optimize tool paths for smooth 3D contours. It calculates the best cutting angles and step-over distances. This reduces scalloping and improves surface finish.

Flat end mills benefit from CAM’s ability to plan efficient material removal strategies. The software can determine ideal cutting depths and widths for each pass.

Adjusting Parameters for Optimal Use

Spindle speed and feedrate are key factors in CNC machining success. For ball nose end mills, higher spindle speeds often yield better results on curved surfaces. This helps maintain consistent cutting forces along the tool’s rounded edge.

Flat end mills may require lower spindle speeds but can handle higher feedrates on flat surfaces. Adjusting these parameters affects:

- Surface finish quality

- Tool wear rate

- Machining time

Proper depth of cut and step-over distance are also crucial. These settings impact tool life and part accuracy.

Tool Longevity and Cost-Efficiency

Extending tool life is vital for cost-effective CNC machining. Ball nose end mills may wear faster when used on flat surfaces due to increased contact area. Using them mainly for contoured surfaces can prolong their lifespan.

Flat end mills often last longer when used for their intended purpose of creating flat surfaces and slots. Regular tool inspection and timely replacement prevent poor surface finishes and part errors.

Coatings can enhance tool durability. TiAlN or AlTiN coatings resist wear and heat, extending the life of both ball nose and flat end mills. This reduces tool replacement costs and machine downtime.

Tool Anatomy and Design Variations

End mills come in different shapes and sizes. Each type has unique features that affect how it cuts metal or other materials.

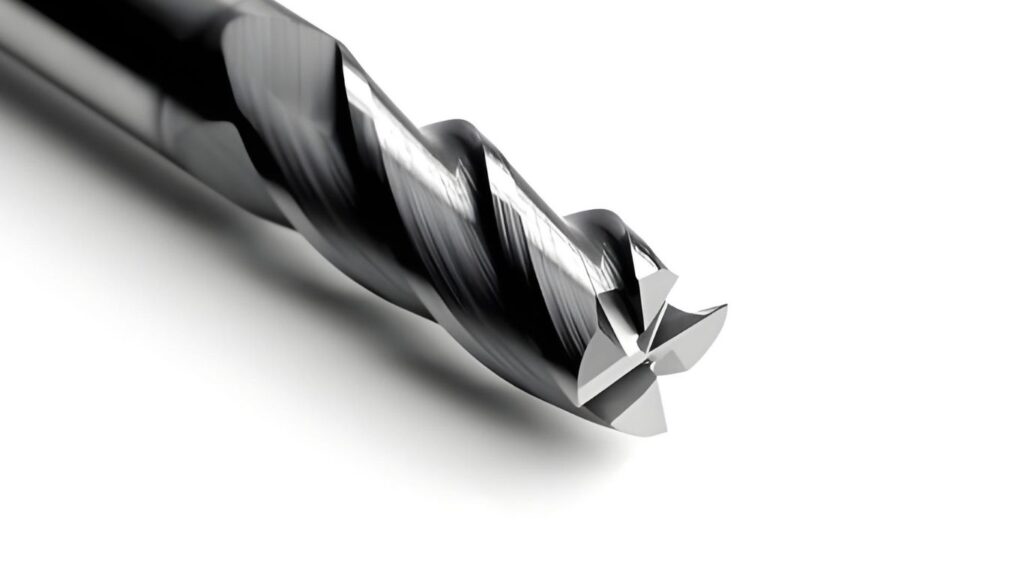

End Mill Types and Their Distinct Features

Flat end mills have a flat bottom and straight sides. They’re good for cutting square edges and flat surfaces. Ball end mills have a rounded tip, like a ball. These work well for curved shapes and 3D contours. Bullnose end mills mix both designs. They have a flat bottom with rounded corners.

Tapered end mills get thinner toward the tip. This shape helps them reach tight spots. Some end mills have special coatings to cut better or last longer.

Understanding Flutes and Cutting Edges

Flutes are the grooves that run up the side of an end mill. They help remove chips as the tool cuts. Most end mills have 2-4 flutes, but some have more.

The helix angle is how much the flutes twist around the tool. A higher angle clears chips faster but can be less stable. The cutting edges are the sharp parts that do the actual cutting.

Upcut flutes pull chips up and away from the cut. This works well for most jobs.

Dimensions and Their Impact on Milling

The size of an end mill affects how it works. Key measurements include:

- Cutting diameter: How wide the tool cuts

- Shank diameter: The part that fits in the machine

- Cutting length: How deep it can cut

- Overall length: Total tool length

- Stickout: How far it sticks out of the holder

Larger tools can remove more material but may not fit in tight spaces. Smaller tools offer more detail but take longer to cut.

The number of flutes also matters. More flutes give a smoother finish but remove material slower. Fewer flutes cut faster but may leave a rougher surface.

Conclusion

Ball nose and flat end mills each have unique strengths. Ball nose mills excel at 3D contours and smooth finishes. Flat end mills are better for flat surfaces and rough cutting.

The choice depends on the job at hand. Ball nose mills work well for curved parts and detailed work. Flat end mills suit 2D shapes and general milling tasks.

Material also matters. Some metals need specific mill types for best results. The number of flutes affects chip removal and cutting stability.

Picking the right tool improves quality and efficiency. It can reduce machining time and extend tool life. Good tool selection leads to better finished products.

Both mill types have a place in most shops. Many projects benefit from using both at different stages. Understanding their strengths helps machinists make smart choices.

Proper use of these tools requires skill and knowledge. With practice, machinists can master when to use each type for optimal results.

Frequently Asked Questions

Ball nose and flat end mills have different shapes and uses in machining. Let’s look at some common questions about these two types of tools.

What are the key differences between a ball nose end mill and a flat end mill in terms of design and functionality?

Ball nose end mills have a rounded tip, while flat end mills have a flat end. The rounded tip of ball nose mills is good for cutting curves and 3D shapes. Flat end mills work better for making flat surfaces and cutting straight slots.

Which applications are best suited for a ball nose end mill over a flat end mill?

Ball nose end mills excel at 3D contouring and finishing curved surfaces. They’re often used in making molds, dies, and parts with complex shapes. Industries like aerospace, automotive, and medical use ball nose mills for parts that need smooth, curved surfaces.

How do the costs of ball nose end mills compare with flat end mills?

Ball nose end mills usually cost more than flat end mills. This is because they have a more complex shape that’s harder to make. The price difference can vary based on size, material, and coating.

In metalworking, when should one opt for a ball nose end mill instead of a flat end mill?

Choose a ball nose end mill when working on curved surfaces or 3D contours. It’s the best choice for finishing operations that need a smooth surface on complex shapes. Flat end mills are better for flat surfaces, straight slots, and squaring up corners.

Can a flat end mill be used to achieve the same results as a ball nose end mill, and if so, under what circumstances?

A flat end mill can sometimes be used instead of a ball nose mill, but it takes more time and skill. For simple curves, a flat end mill can make many small cuts to create a curved shape. But for complex 3D surfaces, a ball nose mill is much more efficient.

What are the specific advantages and disadvantages of using a bull nose end mill in comparison to a flat or ball nose end mill?

Bull nose end mills combine features of both flat and ball nose mills. They have a flat end with rounded corners. This design is stronger than a flat end mill but can still cut flat surfaces. Bull nose mills leave a small radius in corners, which can be good or bad depending on the job.